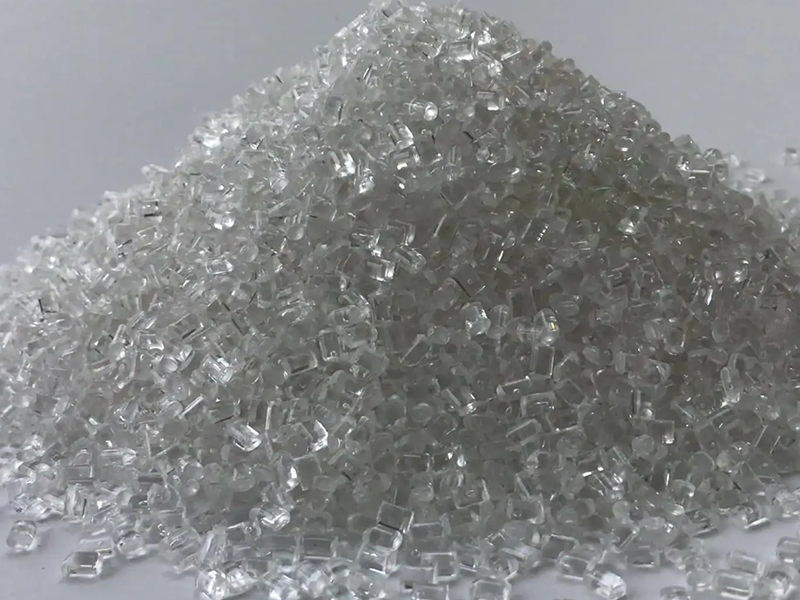

Infrared crystal dryer PET Granulation

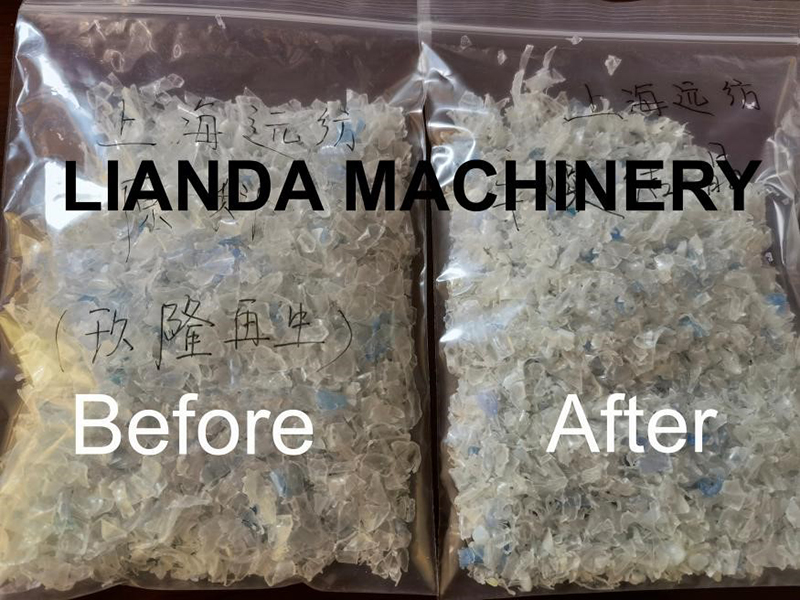

PET Bottle Flake Granulation Line/Double Screw Extruder│ R-PET

Infrared Pre-Drying of PET Flakes: Increasing Output and Improving Quality on PET Extruders

>> Improving the manufacturing and physical properties of recycled, food-grade PET through technology powered by infrared light has a crucial part to play in the intrinsic viscosity (IV) property

Pre-crystallization and drying of the flakes prior to extrusion helps minimize the loss of IV from PET, a critical factor for reuse of the resin

Reprocessing the flakes in the extruder reduces IV due to hydrolysis i the presence of water, and that’s why pre-drying to a homogeneous drying level with our IRD System can limit this reduction. In addtion, the resin does not yellow because drying time is reduced ( Drying time only needs 15-20mins, final moisture can be ≤ 50ppm, energy consumption less than 80W/KG/H), and shearing in the extruder is thereby also reduced because the preheated material enters the extruder at constant temperature”

>> Improving the output of PET Extruder

An increase of the bulk density by 10 to 20 % can be achieved in the IRD, improves the feed performance at the extruder inlet substantially – while the extruder speed remains unchanged, there is a substantially improved filling performance on the screw.

R-PET Flake Pelletizing/Extrusion Line│R-PET

Machine Processing

→ Infrared crystal dryer → Screw feeder → Feeding system → PET Double screw Extruder → Vacuum degassing system

Dewatering machine ←Flushing pelletizier←Flushing water trough←Water cooling strands die head ←Screen changer→Vibrating sieve → Silo storage →

Recyclable Plastics Include

* PET/BOPET bottle flakes, pet film, pet fiber, waste cloth, optical film

* PA66 fishing net, carpet

|

Model |

Screw diameter(mm) |

L/D |

Motor Power(kw) |

Capacity(kg/h) |

|

GTE52B |

52 |

32-60 |

55 |

50-150 |

|

GTE65B |

65 |

32-60 |

90 |

150-350 |

|

GTE75B |

75 |

32-60 |

132 |

400-500 |

|

We can provide you with pelletizing machine as per your requirements. |

||||