Polyester /PET Masterbatch Infrared Crystallization Dryer

Infrared Crystal Dryer + PET Packing Strap/Band Production line

What we can do for you

>> Dry &Crystallize PET Masterbatch in 20mins at 50ppm by saving 45-50% energy cost.

- Up to 60% less energy consumption than conventional drying system

- Uniform crystallization

- No pellets clumped & sticked

- Drying&crystallization in one step

- Carefully material treatment

- Instant start-up and quicker shut down

- Independent temperature and drying time set

- Easy clean and change colour

No segregation of products with different bulk densities

Prevent increasing AA levels for materials with food contact

Infrared crystal dryer working principle

The frequency of infrared is about 1012 C/S ~ 5x1014 C/S, which is part of electromagnetic wave. Near infrared wavelength is 0.75~2.5μ and travels straight at the speed of light, and it goes around the earth seven and a half times per second (about 300,000 Km/s). It can be seen from the light source It is directly transmitted to the material to be heated, causing physical phenomena of absorption, reflection, and transmission.

In addition, the infrared rays that penetrate and reflect from the material do not affect the organization of the material, but the absorbed tissue will be converted into heat energy due to molecular excitation, which causes the temperature of the material to rise. Taking PET as an example, crystallization and crystallization can be achieved in a very short time.

The drying temperature can not only save energy, maintain the physical properties of liposomes and increase the IV value. (The argument to increase the IV value (intrinsic viscosity) needs to be further verified by experiments.)

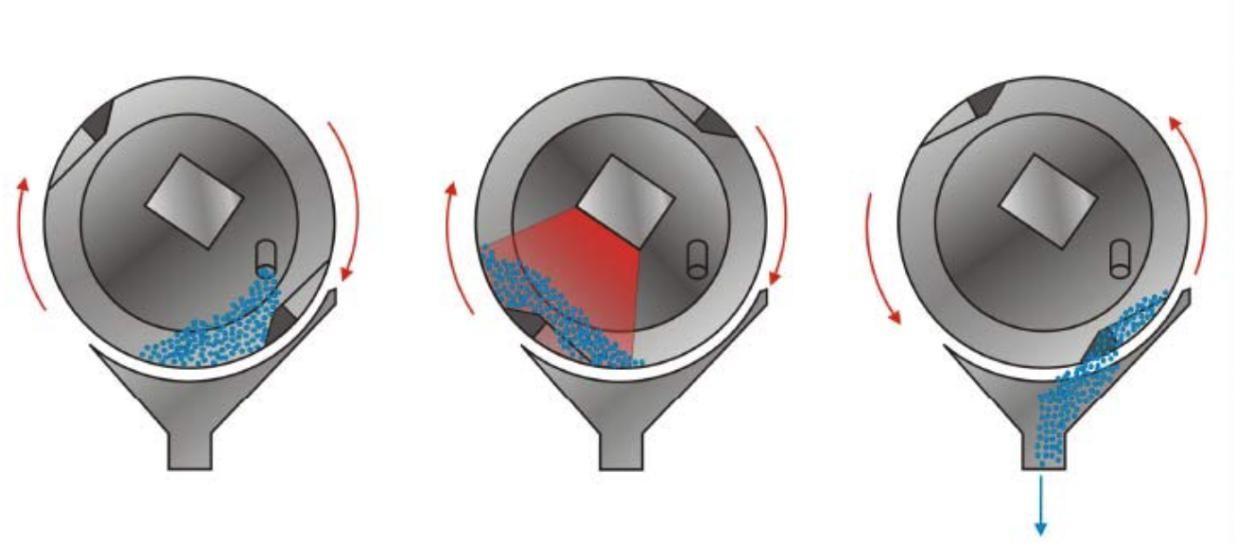

How to work

Feeding/Loading

Dry& Crystallization Processing

Discharging

>>At first step, the only target is to heat up the material to a preset temperature.

Adopt relatively slow speed of drum rotating, the Infrared lamps power of the dryer will be at a higher level, then the PET masterbatch will have a fast heating till the temperature rises to the preset temperature.

>>Drying &Crystallizing step

Once the material gets to the temperature, the speed of the drum will be increased to a much higher rotating speed to avoid the clumping of the material. At the same time, the infrared lamps power will be increased again to finish the drying&crystallization. Then the drum rotating speed will be slowed down again. Normally the drying &crystallization process will be finished after 15-20mins. (The exact time depends on the property of material)

>>After finishing the drying&crystallization processing, the IR Drum will automatically discharge the material and refill the drum for the next cycle.

The automatic refilling as well as all relevant parameters for the different temperature ramps is fully integrated in the state-of-the-art Touch Screen control. Once parameters and temperature profiles are found for a specific material, theses settings can be saved as recipes in the control system.

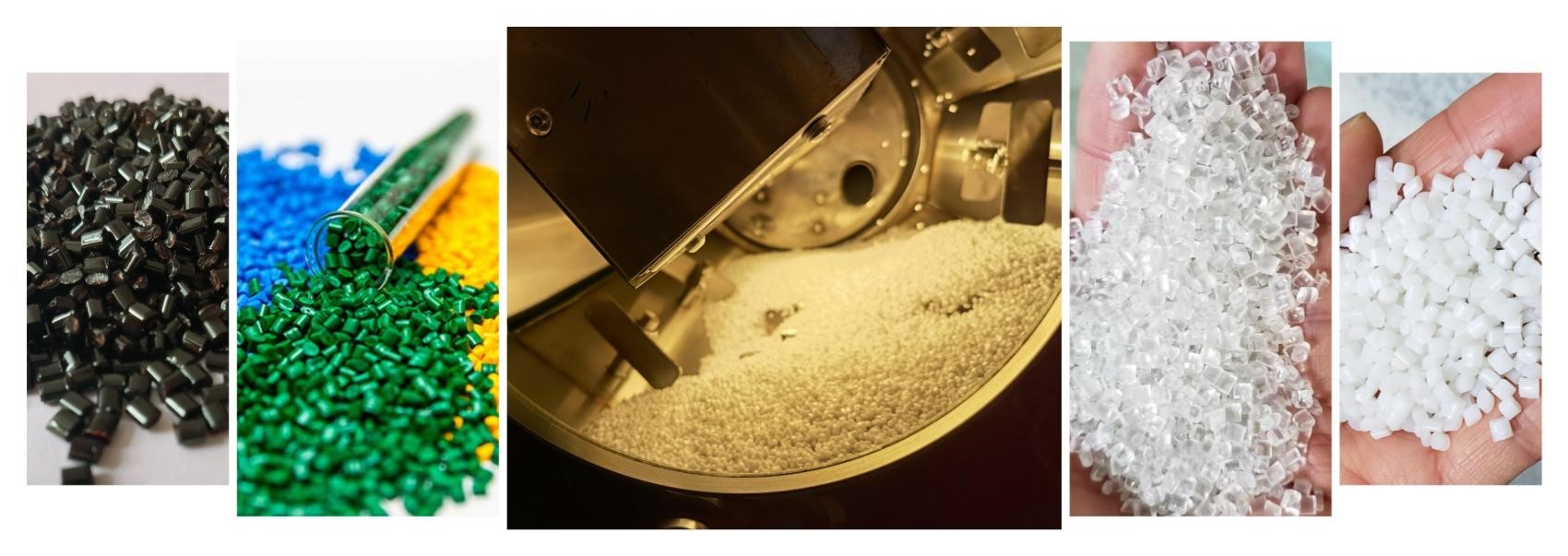

>>If you are the manufacturer of PET Masterbatch, you need to pack the masterbatch and sell

Our machine has equipped with cooling function, will cool the PET Materbatch at 70℃ for package

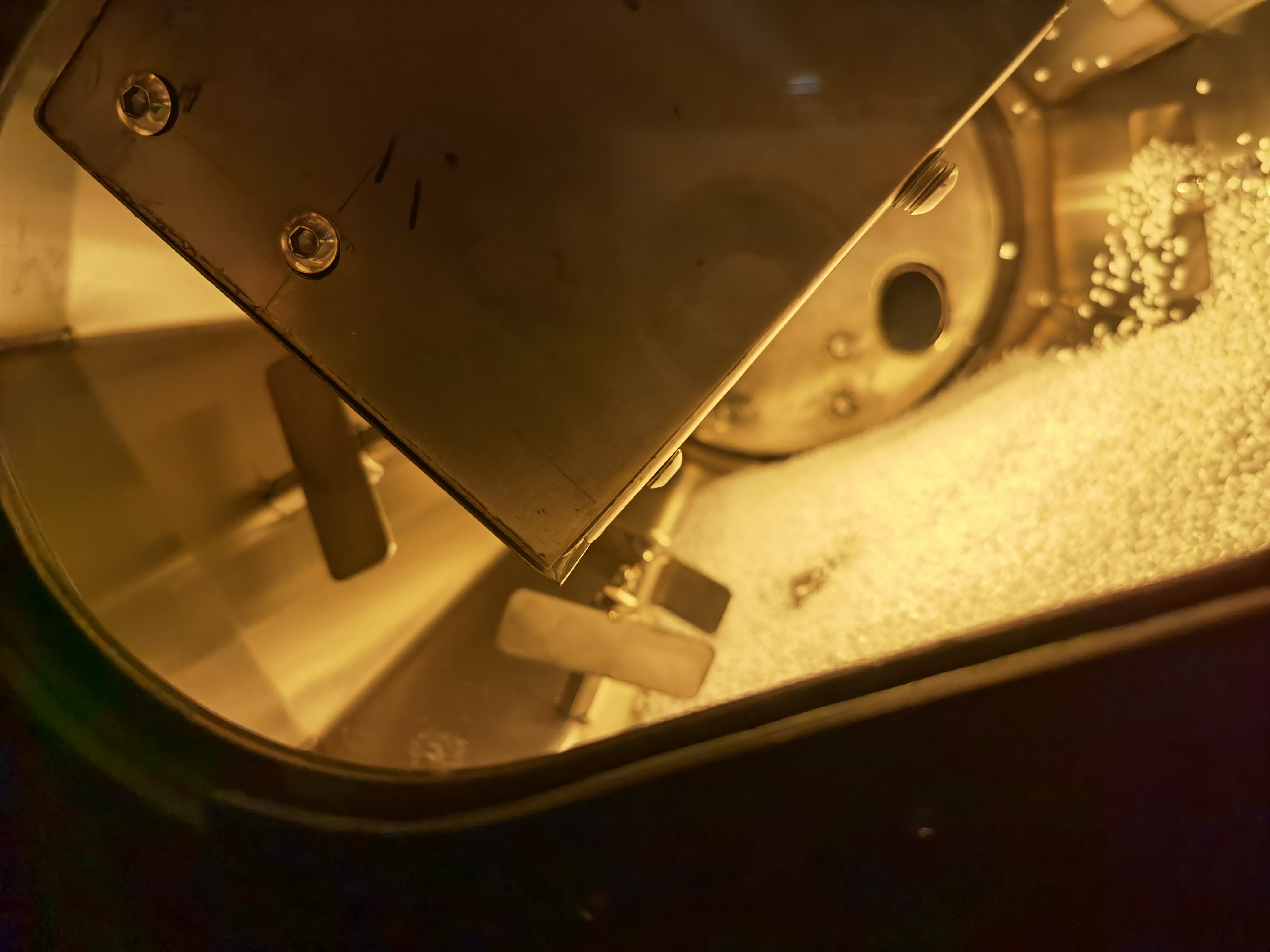

Machine photos for reference

FAQ

Q: During the drying&crystallization processing, if the PET masterbatch is very stick, the masterbatch will be clumped or stick together?

A: To the stick property PET Masterbatch,

>>We have designed the special drying processing to ensure no clumping, no sticking

>>Rotary drum design to avoid any clumping of the material and assure a very good cross mixing of the material

Q: How to clean and change the colour?

A: The drum with the simple mixing elements has no hidden spots and can be cleaned easily with a vacuum cleaner or compressed air. This enables the operator to have a very quick change from one material to another

2) The drum can be separately optional purchase. To change the drum, only needs 3mins.

Q: What’s the drying temperature and time?

A: Independent temperature and drying time set according to the material need.

Q: What’s the electrical cost?

A: Energy consumption less than 100W/KG/HR

Q: We are the manufacture of PET Masterbatch, we sell the masterbatch to others, after the dried& crystallization processing, what’s the output material temperature, we need to package?

A: We have cooling function which can low down the temperature to be about 70℃for package

Q: What’s the delivery time?

A: 45-60 working days

Q: Do you have CE Certificate?

A: Yes, we have