Single shaft shredder

Single shaft shredder

The single-shaft shredder is mainly used to break materials into smaller and uniform pieces.

>>LIANDA single-shaft shredder is equipped with a large inertia blade roller and a hydraulic pusher, which can ensure high output; the moving knife and the fixed knife have high-efficiency and regular cutting actions, and coordinate with the control of the sieve screen,the crushed material can be cut into the expected size.

>>the shredding of almost all types of plastic. Plastic lumps, pipes, automotive scrap, blow-molded materials (PE/PET/PP bottles, buckets, and containers, pallet), as well as paper, cardboard, and light metals.

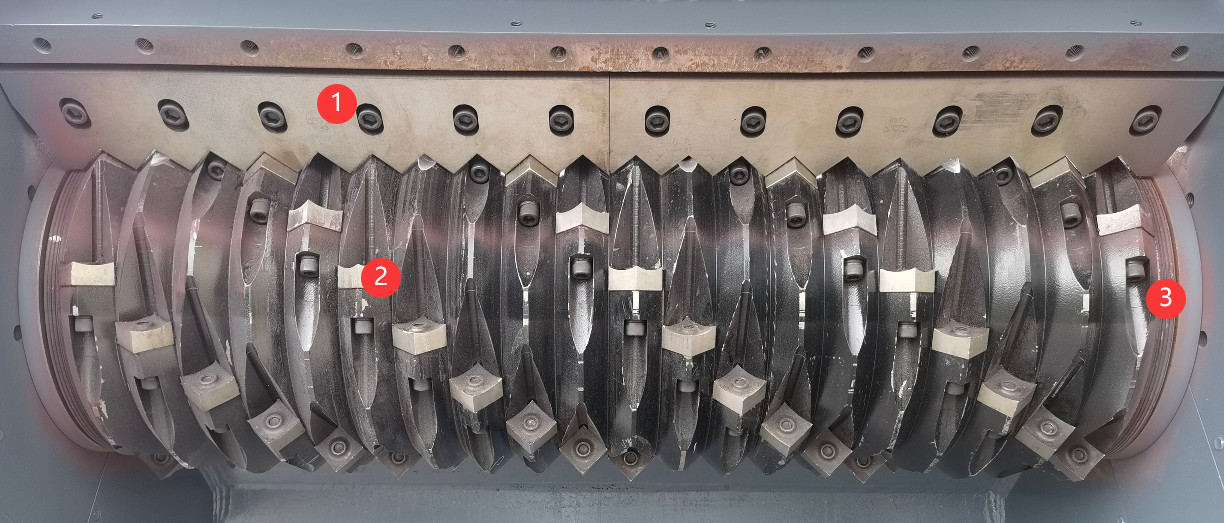

Machine Details Shown

①Stable blade ② Rotary blades

②Blade roller ④ Sieve screen

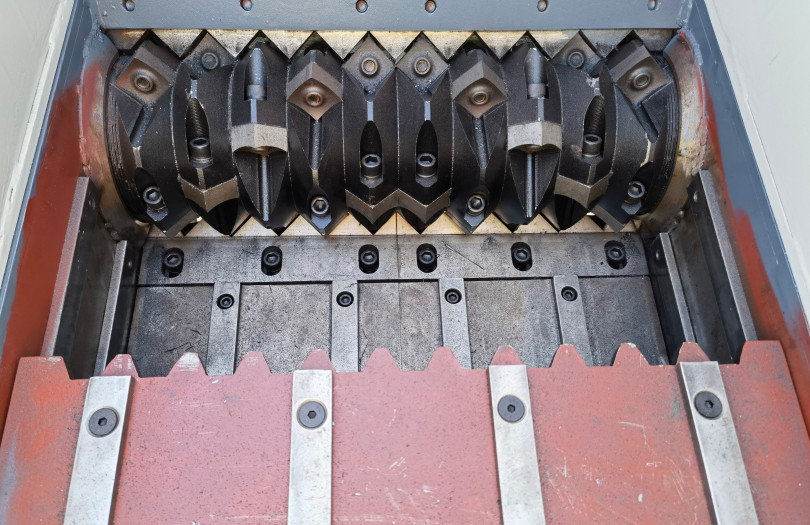

>>The cutting part is composed of a blade roller, rotary blades, fixed blades and sieve screen.

>>The V rotor, specially developed by LIANDA, can be used universally. Its aggressive material feed with up to two rows of knives guarantees high throughput with low power requirements.

>>The screen can be disassembled and replaced to change the particle size of the material

>>Screen can be exchanged flexibly and are bolted as standard.

>>Safe material feed with load-controlled ram

>>The ram, which moves horizontally back and forth via hydraulics, feeds the material to the rotor.

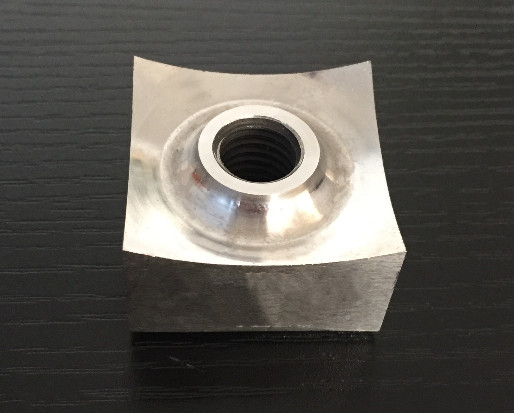

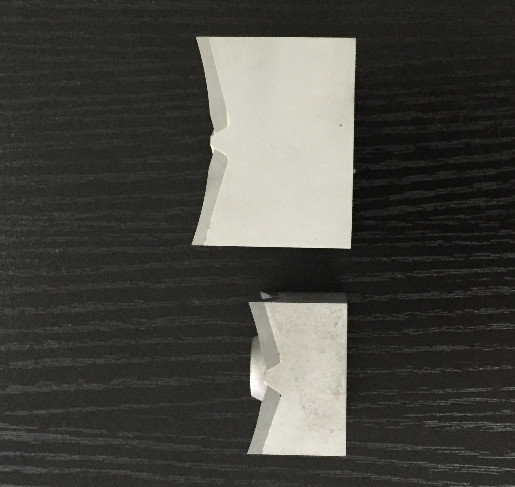

>> Knives in edge lengths of 30 mm and 40 mm. These can be turned over several times in case of wear, which drastically reduces maintenance costs.

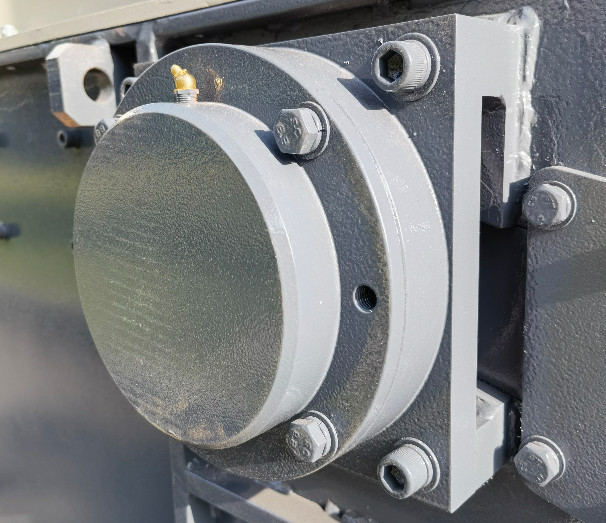

>>Durable rotor bearings thanks to offset design, to prevent dust or foreign matter from getting inside

>> Maintenance-friendly and easy to access.

>>Easy operation by Siemens PLC control with touch display

>>The built-in overload protection also prevents defects in the machine.

Machine Technical parameter

|

Model |

Motor Power (KW) |

Qty of Rotary Blades (PCS) |

Qty of Stable Blades (PCS) |

Rotary Length (MM) |

|

LDS-600 |

22 |

26 |

2

|

600 |

|

LDS-800 |

55 |

45 |

4

|

800 |

|

LDS-1200 |

75 |

64 |

4

|

1200 |

|

LDS-1600 |

132 |

120 |

4

|

1600 |

Application Samples

Plastic lumps

Baled Papers

Wood pallet

Plastic drums

Plastic drums

PET Fiber

KEY FEATURES >>

>>Large diameter flat rotor

>>Machined knife holders

>>Optional hard face

>>Concave ground square knives

>>Robust ram construction

>>Heavy duty guide bearings

>>Universal couplings

>>Low speed, high torque geared drive

>>Powerful hydraulic swing type ram

>>Bolt in driven shafts

>>Multiple rotor designs

>>Ram comb plate

>>Amp meter control

OPTIONS >>

>>Motor power source

>>Sieve screen type

>>Sieve screen need or not

Machine Photos