Infrared Rotary Dryer + SSP system

Solid-phase polymerization (SSP) is the key technology for achieving "quality upgrade" and "green recycling" in the PET industry chain.

LIANDA MACHINERY deeply integrates INFRARED ROTARY DRYER with the SSP system to form an integrated solution of "Efficient moisture remove - Precise viscosity increase - Low-consumption operation". This significantly improves rPET physical properties, thermal stability and chemical purity. This technology plays an irreplaceable role in the PET industry chain (especially high-quality recycling and high-performance product production).

If you need to know the specific process parameters or equipment configuration, please contact Lianda Machinery to obtain customized technical solutions

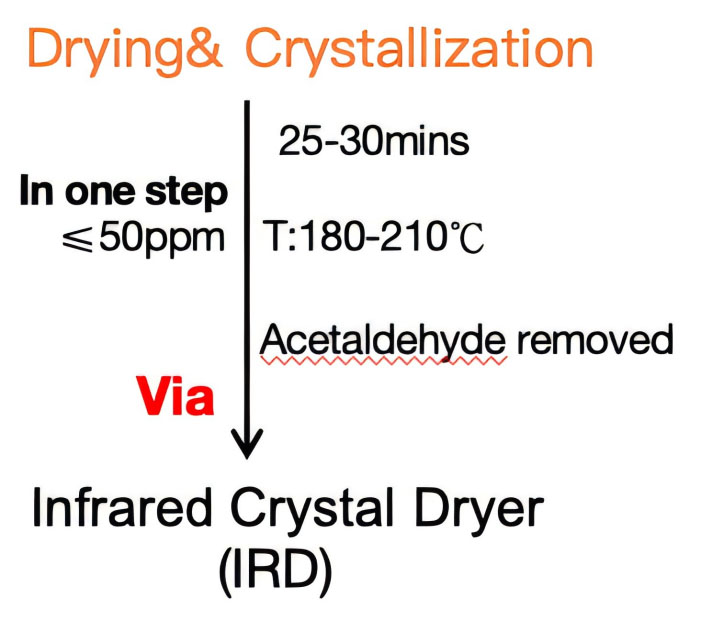

Pre-processing Stage

Drying: PET is hygroscopic and needs to be removed by IRD(After IRD, the PET final moisture ≤ 50 ppm) to avoid hydrolysis and degradation at high temperatures.

Crystallization: PET pellets are crystallized by IRD (crystallization degree is about 30-40%) to prevent the PET pellets from sticking or melting in subsequent high temperatures, while providing a stable solid environment for polycondensation reactions.

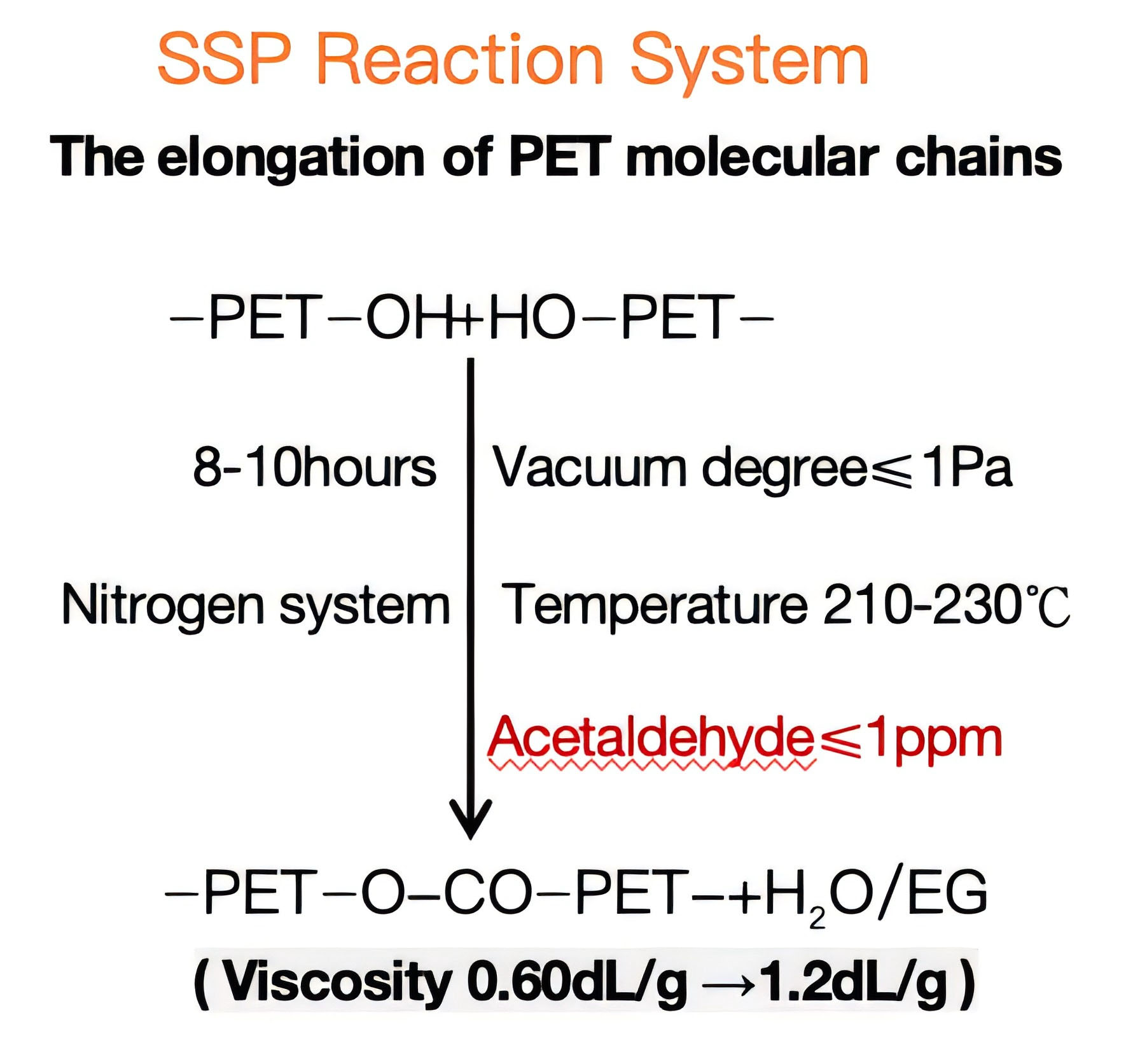

Solid-phase Polycondensation Reaction Stage

➢ Reaction conditions:

Temperature: controlled at 200–240℃ (lower than PET melting point 250–260℃, keep solid).

Vacuum/inert gas flow: nitrogen is introduced and vacuum is drawn to remove the reaction byproduct ethylene glycol (EG) and promote the polycondensation reaction in the positive direction.

➢ Chemical reaction:

The hydroxyl (-OH) and carboxyl (-COOH) at the end of the PET molecular chain undergo condensation reaction to form an ester bond (-COO-), while releasing ethylene glycol (EG), so that the molecular chain continues to extend and the molecular weight (intrinsic viscosity IV) gradually increases.

Lianda Machinery integrates infrared drying (IRD) with the SSP system, quickly and evenly heats the material through infrared rays, shortens the pretreatment time, and optimizes the mass transfer efficiency in the solid phase reaction, so that the whole system has the characteristics of high efficiency and energy saving, large processing capacity, and high product stability, which is especially suitable for the high-quality production of recycled PET.

LIANDA MACHINERY integrates Infrared crystal dryer (IRD) with the SSP system, which uses infrared wave to quickly and evenly heat the material, shorten the pre-treatment time, and optimize the mass transfer efficiency in the solid phase reaction, making the entire system highly energy-efficient, with large processing capacity and high product stability. It is especially suitable for large-scale high-quality production of recycled PET.

If you need further technical details or customized solutions, you can contact Lianda Machinery for professional support

In combination with infrared drying technology, it realizes the integration of "decontaminated + drying + viscosity enhancement", promoting the closed-loop recycling of PET.

In combination with infrared drying technology, it realizes the integration of "decontaminated + drying + viscosity enhancement", promoting the closed-loop recycling of PET.

|

Advantage |

Specific Performance |

|

Molecular weight increase |

The intrinsic viscosity (IV) is significantly increased and the mechanical strength (tensile strength, elastic modulus) is improved by 30–50%. |

|

Thermal stability optimization |

The melting point (Tm) is slightly increased (about 5–10℃), the crystallinity is improved, and the high temperature resistance is enhanced (suitable for heat-resistant bottle preforms). |

|

Improved chemical purity |

Removes residual monomers (such as formaldehyde, acetaldehyde) and oligomers (content drops to less than 50 ppm), meeting food grade standards. |

|

Gentle handling properties |

Solid-state reactions avoid thermal oxidative degradation caused by high-temperature melting and are particularly suitable for quality restoration of recycled PET. |

|

Process flexibility |

The viscosity of the final product can be precisely controlled by adjusting the temperature, time and vacuum degree, thus meeting various demands. |

Application

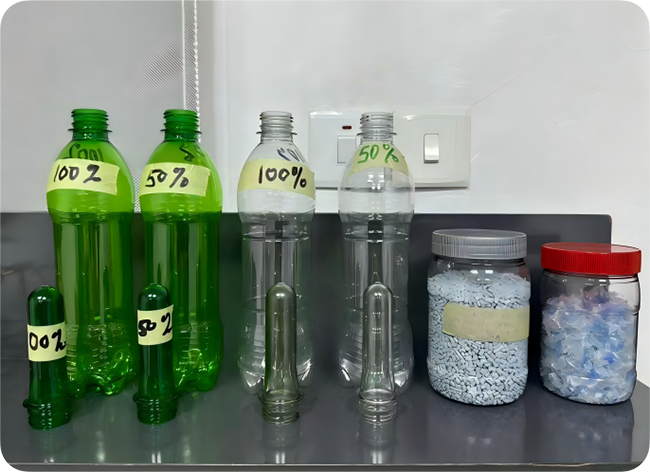

PET Preform

● High transparency bottle production:

Enhances the uniformity of PET viscosity, reduces stress cracking of the bottle body, suitable for carbonated beverages, cosmetic containers, etc.

● Heat-resistant bottle development:

Via SSP, the IV value is increased to above 0.85 dL/g, suitable for heat-filled beverage bottles (such as packaging for instant tea, coffee).

Recycled PET quality upgrade

● Recycling of recycled bottle flakes:

Post-consumer PET bottle flakes are treated with an integrated process of "drying - decontaminated - viscosity enhancement" to remove EG,Acetaldehyde, VOC and restore viscosity, returning them to food-grade or industrial-grade applications (such as fibers, sheets).

● Circular economic value:

Combined with infrared drying (IRD) technology, "low-energy dehydration + efficient viscosity enhancement" is achieved to promote closed-loop recycling of PET

Engineering plastics field

● High-performance PET preparation:

Production of high-viscosity PET (IV>1.0 dL/g) for use in automotive parts (such as gears, bearings), electronic and electrical housings, etc., to replace traditional engineering plastics.