LIANDA MACHINERY is at the forefront of innovation with our state-of-the-art Polyester/PET Masterbatch Infrared Crystallization Dryer. This advanced machinery is specifically designed to address the challenges faced in the drying and crystallization of PET Masterbatch, ensuring a seamless and efficient process.

Cutting-Edge Design for Optimal Performance

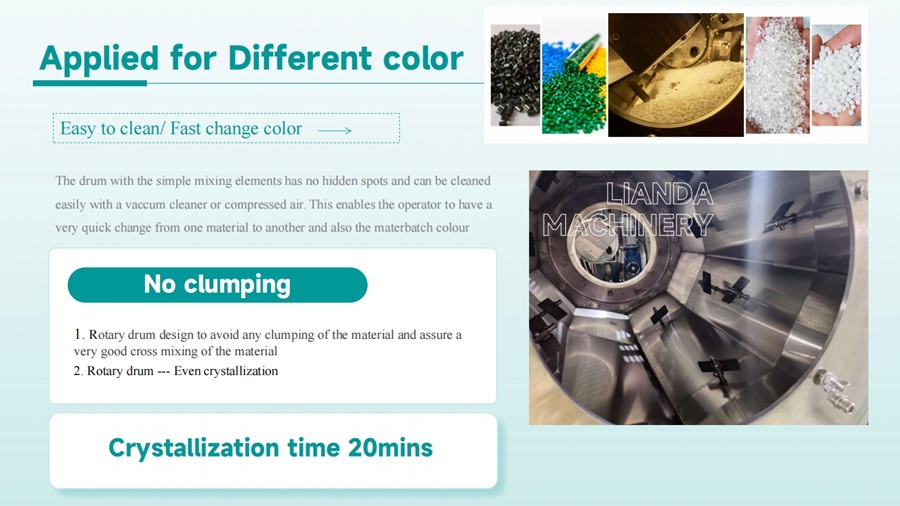

Our dryer boasts a unique rotary drum design that prevents clumping and sticking of materials, ensuring uniform crystallization and excellent cross-mixing. The specialized drying process is tailored to handle the stick property of PET Masterbatch, delivering a clump-free result.

Efficient and Energy-Saving Operation

The dryer operates with remarkable energy efficiency, consuming up to 60% less energy than conventional systems. It can dry and crystallize PET Masterbatch in just 20 minutes at 50ppm, saving 45-50% in energy costs. This not only benefits the environment but also reduces operational expenses.

Advanced Infrared Technology

Utilizing infrared frequencies ranging from 1012 C/S to 5×1014 C/S, our dryer ensures that the material is heated directly, leading to absorption, reflection, and transmission phenomena. The near-infrared wavelength of 0.75-2.5μm penetrates the material without altering its structure, converting absorbed energy into heat for rapid crystallization.

User-Friendly Interface and Control

The dryer is equipped with a modern touch screen control system that allows for instant start-up and quick shutdown. It provides independent regulation of temperature and drying time, with the ability to save specific settings as recipes for future use. This feature ensures consistent quality and simplifies the operation process.

Versatile and Hygienic

Designed with versatility in mind, our dryer can handle a wide range of crystallization temperatures and is easy to clean and change colors, making it suitable for various applications. It also prevents the increase of acetaldehyde (AA) levels in materials intended for food contact, ensuring safety and compliance with industry standards.

Final Product Cooling

For manufacturers of PET Masterbatch, our machine includes a cooling function that cools the material to 70℃ for packaging. This ensures that the masterbatch is ready for immediate distribution and sale.

In summary, the Polyester/PET Masterbatch Infrared Crystallization Dryer from LIANDA MACHINERY is a groundbreaking solution that offers unparalleled efficiency, energy savings, and quality control. It is an essential addition to any PET Masterbatch production line, promising to elevate the standard of your products and processes.

For more information, please contact us:

Email: sales@ldmachinery.com / liandawjj@gmail.com

WhatsApp: +86 13773280065 / +86-512-58563288

Post time: Mar-28-2024