PET sheet is a plastic material that has many applications in packaging, food, medical, and industrial sectors. PET sheet has excellent properties such as transparency, strength, stiffness, barrier, and recyclability. However, PET sheet also requires a high level of drying and crystallization before extrusion, to ensure its quality and performance. Conventional drying and crystallization systems are often time-consuming, energy-intensive, and prone to moisture-related problems.

To overcome these challenges, LIANDA MACHINERY, a company that specializes in plastic recycling and processing equipment, has developed a novel solution for drying and crystallization of PET regrind flake and virgin resin, called the IRD Dryer. The IRD Dryer is a machine that uses infrared radiation and rotation drying system to achieve fast, efficient, and uniform drying and crystallization of PET material in one step. The IRD Dryer has many advantages over conventional systems, such as:

• No segregation of products with different bulk densities

• Instant start-up and quicker shut down

• Low energy consumption and high product quality

• Wide application and easy operation

• PLC control and touch screen interface

In this article, we will describe the detailed product properties and performance of the IRD Dryer for PET sheet production line, and how it can improve the efficiency, quality, and profitability of PET sheet making.

How the IRD Dryer Works

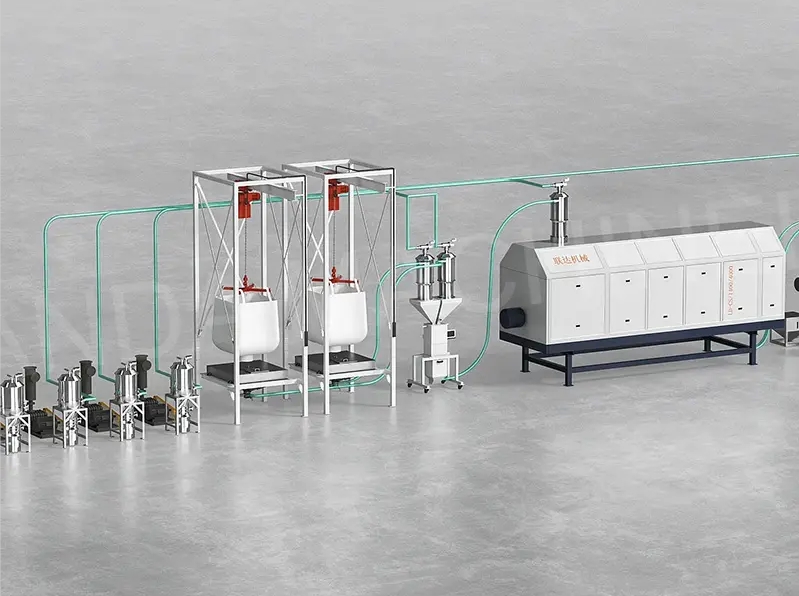

The IRD Dryer is a machine that consists of a rotary drum, a radiator module, a feeding device, a discharge device, and a control system. The IRD Dryer works as follows:

• The PET material, either regrind flake or virgin resin, is fed into the rotary drum by the feeding device, which can be a volumetric dosing unit or a film roll feeding device, depending on the type of material.

• The rotary drum is equipped with spiral coils and mixing elements, which ensure a good mixing and movement of the material inside the drum. The rotary drum can adjust its speed and direction according to the process conditions and the material properties.

• The radiator module is located above the rotary drum, and it emits short-wave infrared radiation, which penetrates into the core of the material and heats it up rapidly. The radiator module is cooled by a continuous air flow, and protected by an air shield, which prevents dust particles from entering and moisture from escaping.

• The infrared radiation causes the material to undergo drying and crystallization simultaneously, as the heat flow pushes the moisture from the inside to the outside of the material, and the molecular structure of the material changes from amorphous to crystalline. The moisture is then removed by the air circulation inside the machine.

• The drying and crystallization process takes about 15 to 20 minutes, depending on the material and the desired final moisture level. The IRD Dryer can achieve a final moisture level of less than 50 ppm, which is suitable for PET sheet extrusion.

• After the drying and crystallization process is completed, the rotary drum automatically discharges the material and refills the drum for the next cycle. The discharge device can be a screw conveyor or a vacuum system, depending on the material and the downstream equipment.

• The IRD Dryer is controlled by a state-of-the-art PLC system, which monitors and regulates the process parameters, such as material and exhaust air temperature, fill level, retention time, radiator power, and drum speed. The PLC system also has a touch screen interface, which allows the operator to set and save the process parameters and temperature profiles for different materials as recipes, and to access the online service via modem.

The IRD Dryer is a simple and effective machine that can dry and crystallize PET material in one step, using infrared radiation and rotation drying system.

The Advantages of the IRD Dryer

The IRD Dryer has many advantages over conventional drying and crystallization systems, such as:

• No segregation of products with different bulk densities: The rotation drying system ensures a constant movement and mixing of the material, regardless of its size, shape, or density. This prevents the material from segregating or clumping during the drying and crystallization process, and ensures a uniform and consistent product quality.

• Instant start-up and quicker shut down: The IRD Dryer does not require pre-heating or cooling down, as the infrared radiation can heat up and cool down the material instantly. This reduces the start-up and shut down time, and increases the flexibility and productivity of the production line.

• Low energy consumption and high product quality: The IRD Dryer uses infrared radiation, which is a direct and efficient way of heating the material, without wasting energy on heating the air or the machine. The IRD Dryer also uses a short drying and crystallization time, which reduces the energy consumption and the thermal degradation of the material. The IRD Dryer can achieve a low energy cost of 0.08 kWh/kg, without sacrificing the product quality.

• Wide application and easy operation: The IRD Dryer can handle various types of PET material, such as regrind flake, virgin resin, film roll, or mixed material. The IRD Dryer can also be used for other plastic materials, such as PE, PP, PVC, ABS, PC, and PLA, as well as other free-flowing bulk materials, such as adhesives, powders, and granules. The IRD Dryer is easy to operate and maintain, as it has a simple structure, a small footprint, and a user-friendly interface.

• PLC control and touch screen interface: The IRD Dryer is controlled by a PLC system, which provides total process visibility and control. The PLC system can monitor and adjust the process parameters, store and recall the recipes, and provide online service via modem. The PLC system also has a touch screen interface, which allows the operator to set and change the process parameters and temperature profiles, and to access the data and the status of the machine.

The IRD Dryer is a machine that can improve the efficiency, quality, and profitability of PET sheet production line, by providing a fast, efficient, and uniform drying and crystallization of PET material in one step.

Conclusion

The IRD Dryer for PET sheet production line is a machine that uses infrared radiation and rotation drying system to achieve drying and crystallization of PET regrind flake and virgin resin in one step. The IRD Dryer has many advantages over conventional systems, such as no segregation of products with different bulk densities, instant start-up and quicker shut down, low energy consumption and high product quality, wide application and easy operation, and PLC control and touch screen interface. The IRD Dryer is a novel solution for PET sheet making, developed by LIANDA, a company that specializes in plastic recycling and processing equipment. The IRD Dryer is a valuable and versatile product in the plastic industry.

For further information or inquiries, please contact us:

Email: sales@ldmachinery.com / liandawjj@gmail.com

WhatsApp: +86 13773280065 / +86-512-58563288

Post time: Dec-27-2023