Are you struggling to find a reliable Automatic Knife Grinding Machine supplier for your factory? Do you worry about machine quality, cost, or whether it will suit your specific production needs? Many factory managers face this challenge, especially when choosing equipment that directly affects blade performance and production efficiency. The wrong choice can lead to uneven grinding, frequent maintenance, or wasted materials.

When you are purchasing industrial knives or blades, you need a machine that is precise, durable, and easy to operate. In this article, you will learn how to evaluate manufacturers, what features to prioritize, and why picking the right company matters for your production line. By the end, you will understand how to make a smart investment that improves productivity, reduces downtime, and ensures consistent blade quality.

Why Picking the Right Automatic Knife Grinding Machine Companies Matters

Choosing the right manufacturer can save you significant time, money, and frustration. Not all suppliers offer the same level of quality, and even small differences in machine stability or precision can greatly affect your production efficiency. For example, a grinding machine that vibrates or is poorly calibrated may damage your blades, slow down your production line, or require frequent repairs, leading to increased downtime and higher operational costs.

Cost-effectiveness matters. Investing in a high-quality Automatic Knife Grinding Machine may have a higher upfront cost, but it often reduces long-term expenses. Reliable machines last longer, require less maintenance, and use energy more efficiently. For instance, a plastics processing company reported that upgrading to a factory-price Automatic Knife Grinding Machine reduced machine downtime by 20% and saved approximately 15% on energy costs, proving that paying for quality upfront can significantly improve your bottom line.

Quality ensures consistent performance. High-quality machines provide precise and even sharpening every time, which directly improves cutting performance and reduces material waste. Some suppliers even guarantee straightness up to ≤0.01mm/m, ensuring blades are perfectly ground. Consistent quality is especially important for companies working with delicate or high-value materials, such as plastic sheets, paper rolls, or food products, where blade accuracy directly impacts final product quality.

Customization meets specific production needs. The right supplier can offer adjustable grinding lengths, optional polishing heads, or specialized suction chucks to handle different types of blades and materials. For example, one client in the plastics industry used a customized machine with an extended grinding length and a strong electromagnetic suction system. The results were impressive: blade life increased by 30%, downtime decreased by 20%, and overall production efficiency improved significantly. Customization ensures that your machine works perfectly for your specific blade types and production requirements, saving money and time in the long term.

Evaluating Automatic Knife Grinding Machine Quality

Quality is the most important factor when buying an Automatic Knife Grinding Machine. A poor-quality machine may produce uneven grinding, damage blades, or require constant repairs, which wastes materials and reduces productivity. When assessing a machine, consider these critical features:

• Grinding straightness ≤0.01mm/m ensures precise results for every blade.

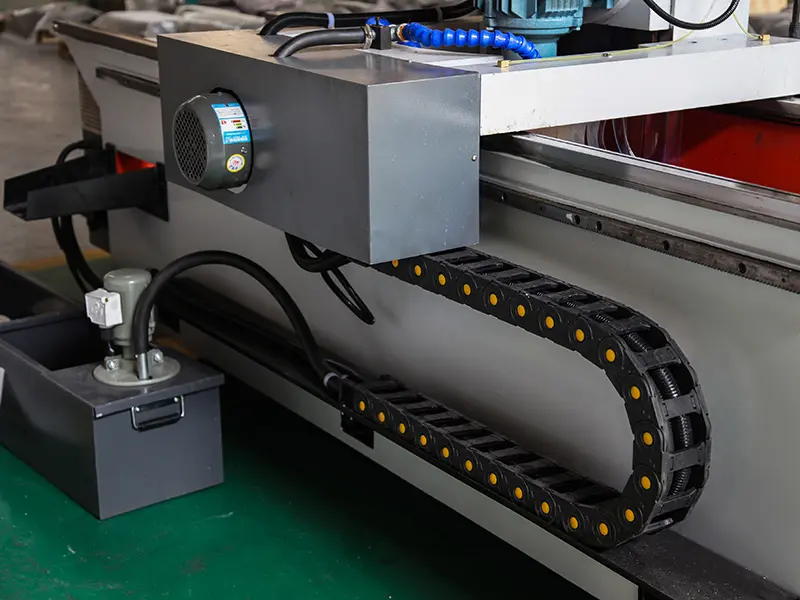

• Stable machine base and gantry structure prevent vibrations that affect accuracy.

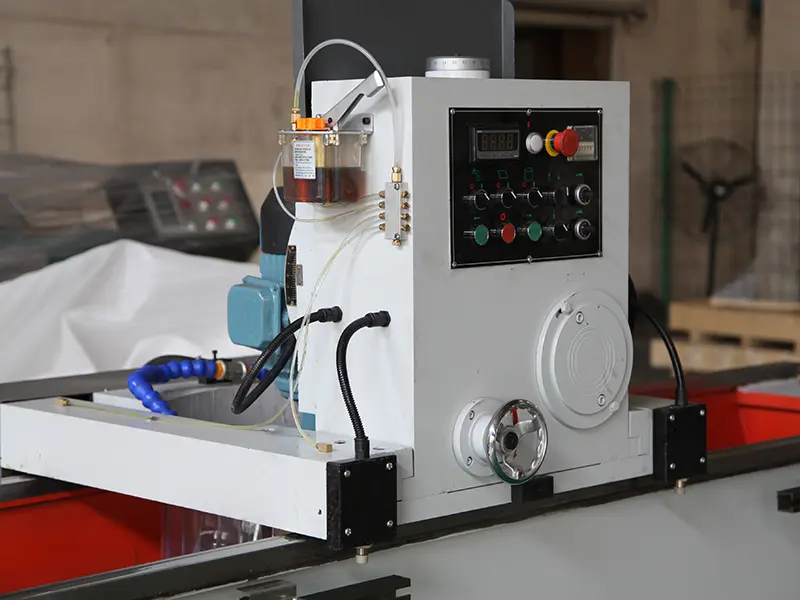

• Powerful electromagnetic suction cup holds blades firmly and accurately.

• PLC-controlled carriage movement guarantees consistent automated grinding cycles.

At Lianda Machinery, quality control is a top priority. Each machine undergoes rigorous testing for precision, stability, and safety before leaving the factory. We hold ISO9001 and CE certificates, and our engineers continuously refine the designs based on real customer feedback. For example, when grinding large plastic machine blades, a stable bed and precise feed control can make the difference between a perfect finish and a blade that requires rework. High-quality machines also reduce energy use, maintenance costs, and the risk of errors, which is critical for large-scale industrial operations.

Right Automatic Knife Grinding Machine Supplier Gives You Precision and Support

A strong manufacturer like Lianda Machinery offers more than just machines. We provide full solutions to ensure your production line operates efficiently and reliably.

• Customization: Grinding lengths range from 1500 mm to 3100 mm or longer for special requirements. Optional polishing heads, fine grinding auxiliary heads, and secondary edge grinding heads allow precise finishing for different blade types.

• Technical support: Our team assists with installation, training, and ongoing maintenance to keep operations running smoothly.

• High performance: Frequency conversion feed, heavy-duty gantry structure, and fast grinding wheel devices increase efficiency and accuracy.

• Cost-effective solutions: Factory-price machines offer stable performance without compromising quality or precision.

• Optional features: Copper coil electromagnetic suction, adjustable axial clearance, and PLC controls allow automatic or manual operation depending on your needs.

This versatility means you can grind a wide range of blades, including crusher blades, paper cutting blades, woodworking planer blades, plastic machine blades, and medical cutters. With the right machine, your factory improves productivity, extends blade life, and reduces waste. Operators also benefit from simple controls and clear interfaces, enabling smoother workflow even during long production runs.

Conclusion

Finding the right Automatic Knife Grinding Machine company is essential for improving production efficiency, saving costs, and maintaining blade performance. By evaluating machine quality, considering customization options, reviewing technical support, and checking precision features, you can select a manufacturer that meets your unique operational needs.

At Lianda Machinery, we combine advanced technology, strict quality control, and years of global experience to provide stable, efficient, and easy-to-use Automatic Knife Grinding Machines. Choosing the right supplier ensures that your blades stay sharp, production lines run smoothly, and your business remains competitive. Remember, investing in a high-quality machine today prevents downtime, reduces waste, and enhances long-term profitability. Whether you operate in plastics, paper, woodworking, or food processing, selecting the right company makes all the difference.

Learn more: Top 5 Automatic Knife Grinding Machine Manufacturers in China

Post time: Oct-22-2025