Imagine a baking scenario. If you use damp flour, the cookies you make will not turn out perfect and will have a soggy texture. The same principle applies when manufacturing products from special plastics like PLA and PBAT. These plastics are commonly used to produce biodegradable items such as food containers and shopping bags. If the tiny plastic pellets contain internal moisture when melted, the final product may suffer from issues like insufficient strength, bubbles, or surface defects.

This is where a professional solution comes into play: the Infrared Crystal Dryer. This guide will explain the working principle of this equipment in a clear and easy-to-understand manner, with a focus on why it is particularly well-suited for processing PLA and PBAT, two important types of biodegradable plastics.

The Moisture Problem with PLA and PBAT

First, what are PLA and PBAT?

- PLA (Polylactic Acid): Made from plants like corn or sugarcane. It’s used for things like disposable cups, food packaging, and 3D printer filament.

- PBAT (Polybutylene Adipate Terephthalate): A flexible, biodegradable plastic often mixed with PLA to make stronger, more bendable products like compostable bags.

These plastics are great for the planet, but they have a quirk: they love to absorb moisture from the air, almost like a sponge. This is a huge headache for factories.

Why is Wet Plastic a Problem?

Melting wet plastic pellets causes a chemical reaction called hydrolysis. This breaks down the plastic’s long, strong chains, making it much weaker. The result?

- Weak, brittle final products.

- Bubbles and holes on the surface (“splay”).

- Inconsistent quality, leading to waste and unhappy customers.

- Clogged machines that need to stop for cleaning.

Traditional hot air dryers are slow and can use a lot of energy. For modern, fast-paced production, a better solution was needed.

The Infrared Solution: Fast, Efficient, and Smart

Enter the Infrared Crystal Dryer. This machine solves the moisture problem in a brilliant and efficient way.

How Does It Work? Simple Science!

Instead of just blowing hot air around, this dryer uses infrared energy. Think of how the sun warms your skin on a bright day—that’s infrared radiation. It transfers heat directly to the plastic pellets without needing to heat up all the air around them first.

Here’s the simple process inside the dryer:

- Feeding: Plastic pellets are gently vacuumed into the rotating drum of the dryer.

- Tumbling & Heating: The drum rotates, tumbling the pellets so they heat evenly. Powerful infrared heaters warm the pellets directly and deeply.

- Smart Control: Sophisticated sensors constantly check the temperature of both the plastic and the air inside. If anything changes, a smart computer (PLC system) adjusts the heat automatically for perfect results.

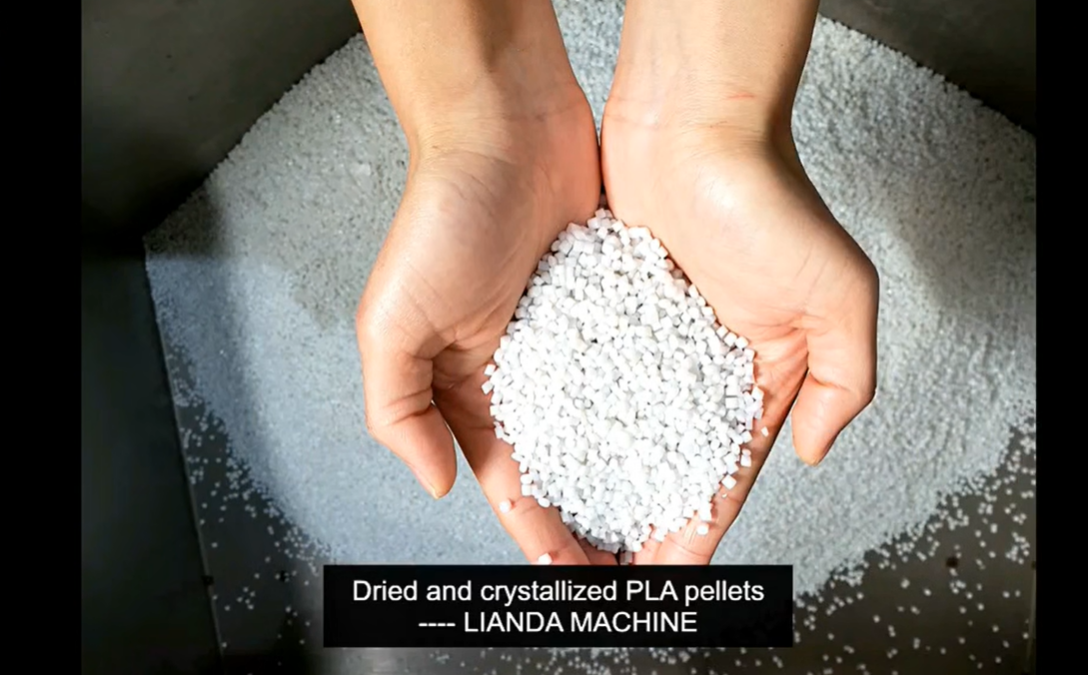

- Fast Results: In just about 20 minutes, the pellets are perfectly dry and crystallized.

- Discharging: The dried, free-flowing pellets are discharged, ready for the next production step.

Why Factories Love This Dryer (The Big Benefits)

This isn’t just another machine. It’s designed to make production easier and better. Here’s why it’s so effective for PLA and PBAT:

- Incredibly Fast: It dries plastic in 20 minutes, not hours. This means factories can run faster and respond to orders more quickly.

- Super Dry Pellets: It can reduce moisture from over 4000 ppm (very wet) down to 50-70 ppm (extremely dry). This level of dryness is what’s needed for top-quality products.

- Huge Energy Savings: Because it heats the plastic directly, it uses 45-50% less energy than old-fashioned dryers. This saves a lot of money and is better for the environment.

- Prevents Clumping: Sticky plastics like PLA can clump together when heated. The dryer’s drum spins at a higher speed to keep the pellets moving and separate, ensuring even drying.

- Simple & Stable Operation: The goal is reliable, “set-it-and-forget-it” performance. The automated controls handle the tricky parts, letting factory managers focus on other tasks.

More Than Just Drying: Other Cool Jobs

The Infrared Crystal Dryer is versatile. Besides drying PLA and PBAT, it can handle many important tasks in a plastic factory:

- Crystallizing PET: Making bottle plastic ready for melting.

- Drying Other Plastics: Like PBT, ABS/PC, and nylon.

- Heating Pellets: Warming up plastics like PVC or PP to help them process smoother later.

- Removing Chemicals: Gently baking out unwanted substances from the plastic.

Conclusion: The Smart Choice for Modern Factories

For any enterprise handling PLA, PBAT, or other sensitive plastics, moisture control is a critical factor determining product quality. The Infrared Crystal Dryer offers a modern solution that integrates three core advantages: high-speed efficiency, exceptional energy savings, and intelligent self-regulation.

Choosing this technology means that companies not only address the challenges of the drying process but also make a strategic investment in production stability, material utilization, operational cost control, and product quality enhancement. As smart manufacturing becomes an inevitable trend, this represents a crucial step for enterprises moving toward efficient and sustainable development.

As a professional manufacturer with over 25 years of expertise in the field of plastic recycling and processing equipment, LIANDA is committed to delivering reliable and innovative technological solutions that provide tangible efficiency for global clients.

Interested in learning more about how this technology can enhance your production efficiency? Explore detailed technical information on the LIANDA Infrared Crystal Dryer now!

Post time: Jan-08-2026