Sistimi ea Infrared Rotary Dryer + SSP

Solid-phase polymerization (SSP) ke theknoloji ea bohlokoa bakeng sa ho fihlela "ntlafatso ea boleng" le "green recycling" letotong la indasteri ea PET.

LIANDA MACHINERY e kopanya ka boteboINFRARED ROTARY DRYER ka sistimi ea SSPho theha tharollo e kopanetsoeng ea "Ho tlosa mongobo o sebetsang hantle - Keketseho e nepahetseng ea viscosity - Ts'ebetso e tlaase ea tšebeliso". Sena se ntlafatsa haholo thepa ea 'mele ea rPET, botsitso ba mocheso le bohloeki ba lik'hemik'hale. Theknoloji ena e bapala karolo e ke keng ea nkeloa sebaka ketane ea indasteri ea PET (haholo-holo ea boleng bo holimo le tlhahiso ea sehlahisoa se sebetsang hantle).

Haeba o hloka ho tseba liparamente tse ikhethileng tsa ts'ebetso kapa tlhophiso ea lisebelisoa, ka kopo ikopanye le Lianda Machinery ho fumana litharollo tse ikhethileng tsa tekheniki.

Mothati oa ho sebetsa pele

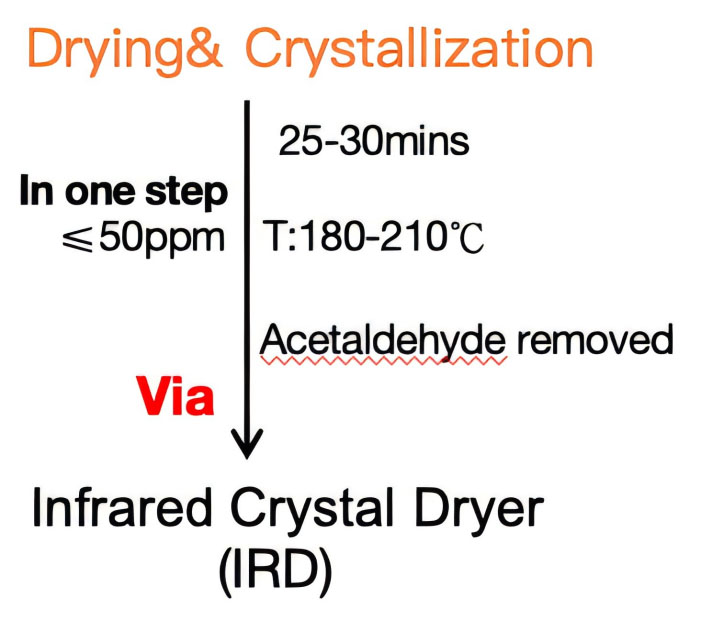

Ho omisa: PET ke hygroscopic mme e hloka ho tlosoa ke IRD (Ka mor'a IRD, mongobo oa ho qetela oa PET ≤ 50 ppm) ho qoba hydrolysis le ho senyeha ha mocheso o phahameng.

Crystallization: Li-pellets tsa PET li khabisitsoe ka IRD (degree ea crystallization e ka bang 30-40%) ho thibela li-pellets tsa PET hore li se ke tsa khomarela kapa tsa qhibiliha ka mocheso o phahameng o latelang, ha li ntse li fana ka tikoloho e tsitsitseng e tiileng bakeng sa karabelo ea polycondensation.

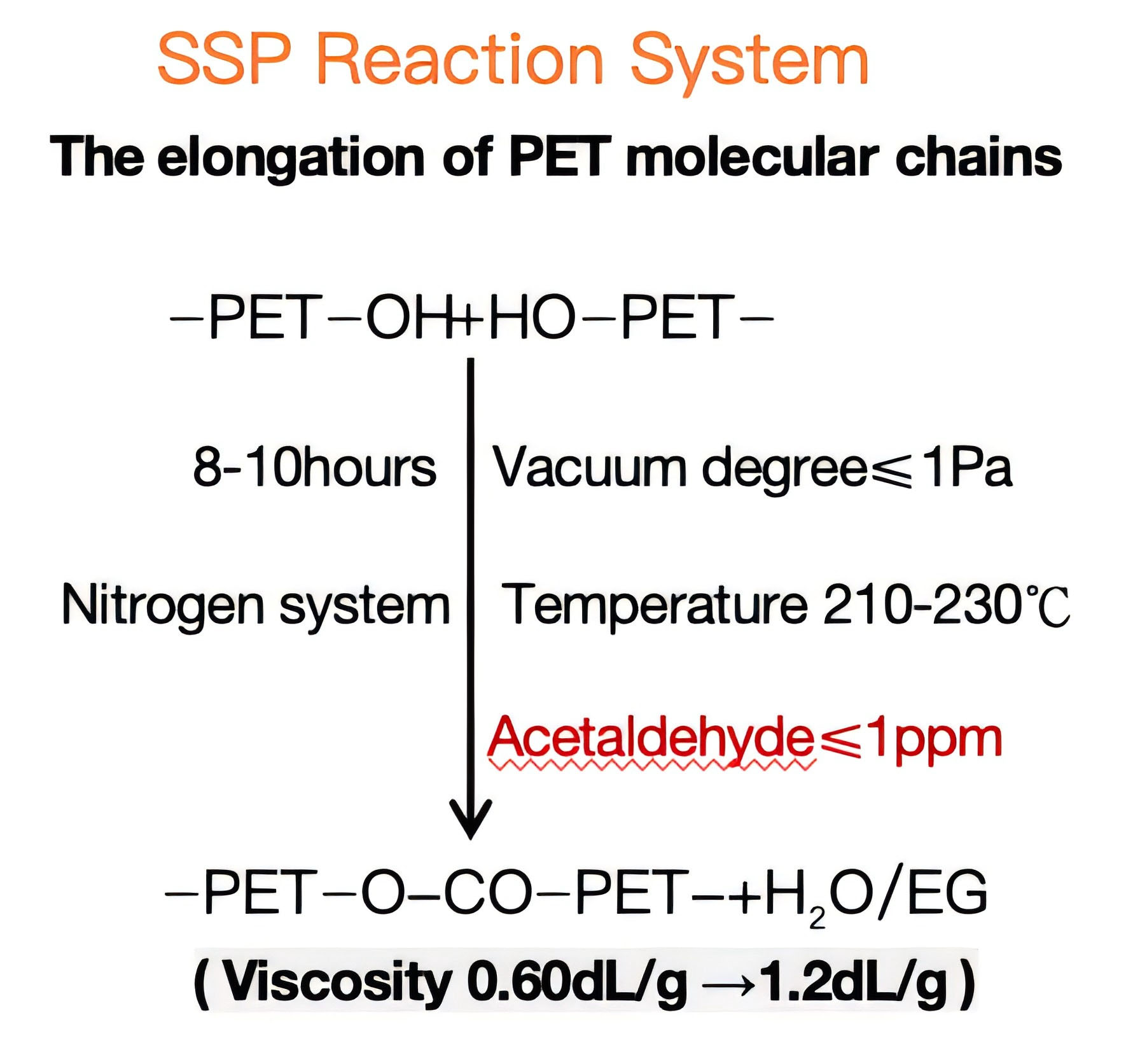

Mokhahlelo o tiileng oa Polycondensation Reaction Stage

➢ Lipehelo tsa ts'ebetso:

Thempereichara: e laoloa ho 200-240 ℃ (e ka tlase ho sebaka se qhibilihang sa PET 250-260 ℃, boloka se tiile).

Phallo ea khase ea vacuum / inert: naetrojene e hlahisoa 'me vacuum e huloa ho tlosa reaction byproduct ethylene glycol (EG) le ho khothaletsa karabelo ea polycondensation ka tsela e nepahetseng.

➢ Tšebetso ea lik'hemik'hale:

Hydroxyl (-OH) le carboxyl (-COOH) qetellong ea ketane ea molek'hule ea PET e kena karabelo ea condensation ho theha ester bond (-COO-), ha e ntse e lokolla ethylene glycol (EG), e le hore ketane ea molek'hule e tsoele pele ho atolosa le boima ba molek'hule (intrinsic viscosity IV) butle-butle e eketseha.

Lianda Machinery e kopanya infrared drying (IRD) le sistimi ea SSP, ka potlako le ka mokhoa o ts'oanang e futhumatsa thepa ka mahlaseli a infrared, e khutsufatsa nako ea pele ho kalafo, mme e ntlafatsa ts'ebetso ea phetisetso ea bongata molemong oa karabelo e tiileng ea karolo, e le hore sistimi eohle e na le litšobotsi tsa ts'ebetso e phahameng le ho boloka matla, matla a maholo a ts'ebetso, le botsitso ba sehlahisoa se phahameng, se loketseng haholo tlhahiso ea boleng bo holimo ea PET.

LIANDA MACHINERY e kopanya Infrared crystal dryer (IRD) le tsamaiso ea SSP, e sebelisang leqhubu la infrared ho futhumatsa thepa ka potlako le ka mokhoa o ts'oanang, ho khutsufatsa nako ea pele ho phekolo, le ho ntlafatsa katleho ea phetisetso ea bongata karabelong e tiileng ea mohato, ho etsa hore tsamaiso eohle e sebetse hantle haholo, e nang le matla a maholo a ho sebetsa le botsitso bo phahameng ba sehlahisoa. E loketse haholo tlhahiso e kholo ea boleng bo holimo ea PET e nchafalitsoeng.

Haeba o hloka lintlha tse ling tsa tekheniki kapa litharollo tse ikhethileng, o ka ikopanya le Lianda Machinery bakeng sa tšehetso ea litsebi

Hammoho le thekenoloji ea ho omisa infrared, e hlokomela ho kopanngoa ha "decontaminated + drying + viscosity enhancement", e khothalletsang ho tsosolosoa ha loop e koetsoeng ea PET.

Hammoho le thekenoloji ea ho omisa infrared, e hlokomela ho kopanngoa ha "decontaminated + drying + viscosity enhancement", e khothalletsang ho tsosolosoa ha loop e koetsoeng ea PET.

| Molemo | Tshebetso e Ikgethileng |

| Ho eketseha ha boima ba limolek'hule | The intrinsic viscosity (IV) e eketsehile haholo 'me matla a mochine (matla a thata, modulus elastic) a ntlafatsoa ka 30-50%. |

| Thermal botsitso optimization | Sebaka se qhibilihisang (Tm) se eketsehile hanyenyane (hoo e ka bang 5-10 ℃), khanya ea kristale e ntlafatsoa, 'me mocheso o phahameng oa mocheso o matlafatsoa (o loketse li-preforms tsa botlolo tse thibelang mocheso). |

| Bohloeki bo ntlafetseng ba lik'hemik'hale | E tlosa li-monomers tse setseng (tse kang formaldehyde, acetaldehyde) le oligomers (li-content li theohela ho tlase ho 50 ppm), li finyella litekanyetso tsa lijo. |

| Lintho tse bonolo tsa ho tšoara | Liphetoho tsa boemo bo tiileng li qoba ho senyeha ha oxidative ea mocheso o bakoang ke ho qhibiliha ha mocheso o phahameng 'me li loketse ka ho khetheha bakeng sa tsosoloso ea boleng ba PET e tsosolositsoeng. |

| Ho fetoha ha maemo | Viscosity ea sehlahisoa sa ho qetela e ka laoloa ka nepo ka ho lokisa mocheso, nako le degree ea vacuum, ka hona ho fihlela litlhoko tse fapaneng. |

Kopo

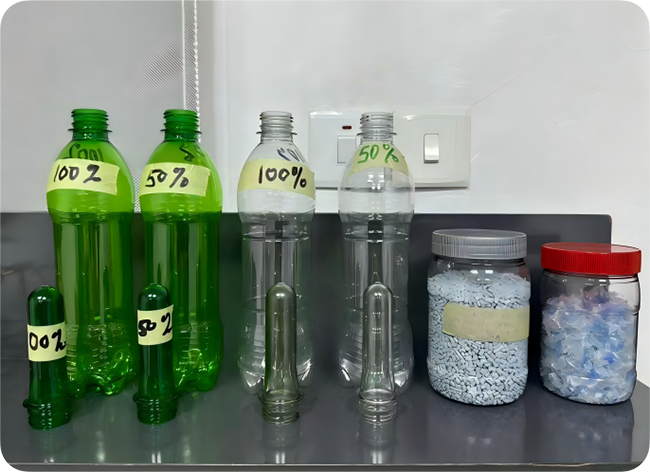

PET Preform

● Tlhahiso ea botlolo e pepeneneng e phahameng:

E ntlafatsa ho tšoana ha PET viscosity, e fokotsa khatello ea maikutlo ea 'mele oa botlolo, e loketseng lino tse nang le carbonate, lijana tsa litlolo, joalo-joalo.

● Nts'etsopele ea botlolo e thibelang mocheso:

Ka SSP, boleng ba IV bo eketsoa ho feta 0.85 dL / g, bo loketseng libotlolo tsa seno tse tletseng mocheso (tse kang ho paka bakeng sa tee ea hang-hang, kofi).

Ntlafatso ea boleng ba PET e nchafalitsoeng

● Recycling of recycled bottle flakes:

Li-flakes tsa botlolo tsa PET tsa post-consumer li tšoaroa ka mokhoa o kopantsoeng oa "ho omisa - ho silafatsoa - ho ntlafatsa viscosity" ho tlosa EG,Acetaldehyde, VOC le ho tsosolosa viscosity, ho li khutlisetsa lits'ebetsong tsa boemo ba lijo kapa tsa indasteri (joalo ka likhoele, maqephe).

● Boleng ba moruo bo chitja:

Ha e kopantsoe le theknoloji ea infrared drying (IRD), "tlaase-energy dehydration + viscosity enhancement e sebetsang hantle" e fihlelleha ho khothaletsa phepelo e koetsoeng ea PET.

Tšimo ea polasetiki ea boenjiniere

● Tokiso ea PET e sebetsang hantle haholo:

Tlhahiso ea PET e nang le viscosity e phahameng (IV> 1.0 dL / g) bakeng sa ho sebelisoa likarolong tsa likoloi (tse kang likere, li-bearings), matlo a elektronike le a motlakase, joalo-joalo, ho nkela lipolasetiki tsa setso tsa boenjiniere.