Infrared Rotary Dryer + SSP system

Solid-phase polymerization (SSP) ndiyo yakakosha tekinoroji yekuwana "mhando yekusimudzira" uye "girinhi kudzokorodza" muPET indasitiri cheni.

LIANDA MACHINERY inobatanidza zvakadzamaINFRARED ROTARY DRYER ine SSP systemkuumba sarudzo yakabatanidzwa ye "Inoshanda mwando bvisa - Yakananga viscosity kuwedzera - Low-consumption operation". Izvi zvinovandudza zvakanyanya rPET zvivakwa zvemuviri, kugadzikana kwemafuta uye kuchena kwemakemikari. Iyi tekinoroji inoita basa risingadzokerike muPET indasitiri cheni (kunyanya yemhando yepamusoro kudzokorodza uye yepamusoro-inoshanda chigadzirwa kugadzirwa).

Kana iwe uchida kuziva iwo chaiwo maitiro paramita kana gadziriso yemidziyo, ndapota taura neLianda Machinery kuti uwane yakagadziriswa tekinoroji mhinduro.

Pre-processing Stage

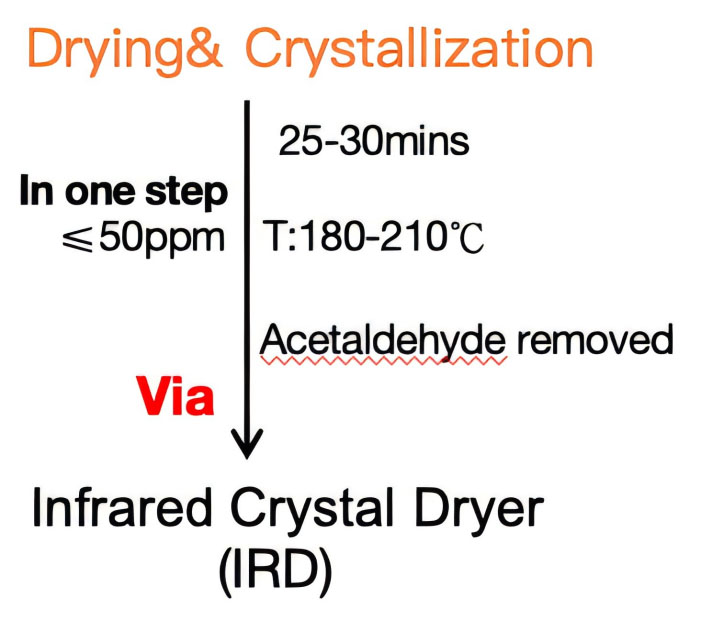

Kuomesa: PET ndeye hygroscopic uye inoda kubviswa ne IRD (Mushure me IRD, iyo PET yekupedzisira mwando ≤ 50 ppm) kudzivirira hydrolysis uye kuderera pakupisa kwakanyanya.

Crystallization: PET pellets inonatswa neIRD (crystallization degree ingangoita 30-40%) kudzivirira PET pellets kubva kunamira kana kunyunguduka mune inotevera tembiricha yepamusoro, ichipa yakagadzikana yakasimba nharaunda yepolycondensation maitiro.

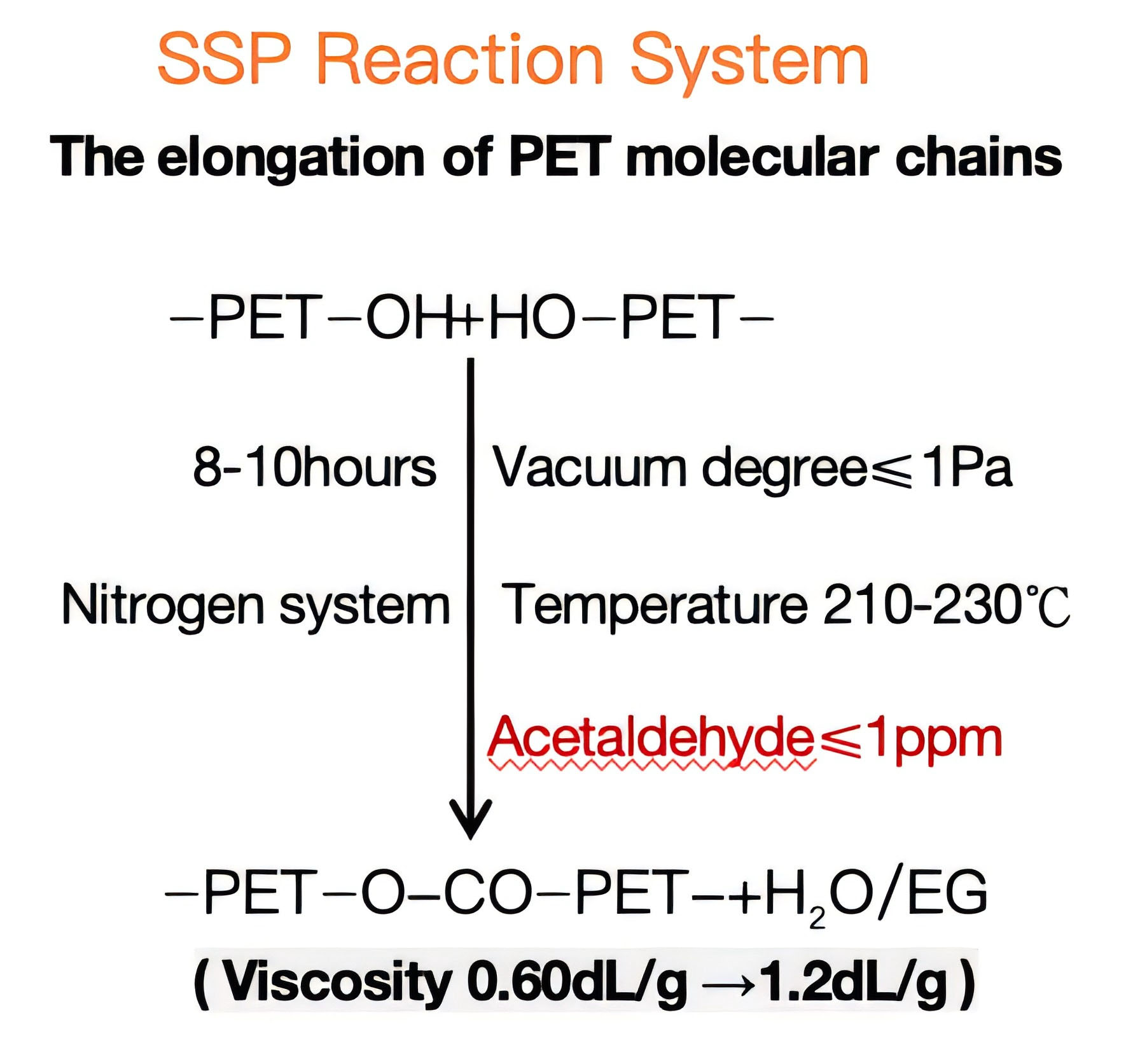

Solid-phase Polycondensation Reaction Stage

➢ Maitiro ekuita:

Tembiricha: inodzorwa pa200-240 ℃ (yakaderera pane PET inonyungudika 250-260 ℃, ramba wakasimba).

Vacuum / inert gasi kuyerera: nitrogen inounzwa uye vacuum inokweverwa kuti ibvise maitiro neproduct ethylene glycol (EG) uye kukurudzira iyo polycondensation reaction munzira yakanaka.

➢ Chemical reaction:

Iyo hydroxyl (-OH) uye carboxyl (-COOH) pamagumo ePET molecular chain inopinda condensation reaction kuti iite ester bond (-COO-), ichibudisa ethylene glycol (EG), kuitira kuti cheni ye molecular irambe ichiwedzera uye molecular weight (intrinsic viscosity IV) inowedzera zvishoma nezvishoma.

Lianda Machinery inobatanidza infrared drying (IRD) neSSP system, nekukurumidza uye zvakaenzana kupisa zvinhu kuburikidza nemwaranzi ye infrared, inopfupisa nguva yekugadzirira, uye inogonesa kufambiswa kwemazhinji muyakasimba chikamu chekuita, kuitira kuti sisitimu yese ive nehunhu hwekushanda kwakanyanya uye kuchengetedza simba, hukuru hwekugadzirisa, uye yakakwira chigadzirwa kugadzikana, iyo inonyanya kukodzera kugadzirwa kwemhando yepamusoro yePET.

LIANDA MACHINERY inobatanidza Infrared crystal dryer (IRD) neSSP system, iyo inoshandisa infrared wave kukurumidza uye zvakaenzana kupisa zvinhu, kupfupisa nguva isati yatanga kurapwa, uye kukwidziridza kushandiswa kwehuwandu muhutano hwakasimba hwekuita, zvichiita kuti hurongwa hwese huve nesimba, huine simba guru rekugadzirisa uye kugadzikana kwechigadzirwa. Iyo inonyanya kukodzera kune yakakura-yemhando yepamusoro kugadzirwa kwePET yakadzokororwa.

Kana iwe uchida humwe ruzivo rwehunyanzvi kana zvigadziriso zvakagadziridzwa, unogona kubata Lianda Machinery kuti uwane rutsigiro rwehunyanzvi

Mukubatana ne infrared drying tekinoroji, inoona kubatanidzwa kwe "decontaminated + drying + viscosity enhancement", ichisimudzira yakavharwa-loop recycling yePET.

Mukubatana ne infrared drying tekinoroji, inoona kubatanidzwa kwe "decontaminated + drying + viscosity enhancement", ichisimudzira yakavharwa-loop recycling yePET.

| Advantage | Specific Performance |

| Molecular uremu kuwedzera | Iyo intrinsic viscosity (IV) yakawedzera zvakanyanya uye iyo mechanical simba (tensile simba, elastic modulus) inovandudzwa ne30-50%. |

| Thermal kugadzikana optimization | Iyo yekunyungudika (Tm) yakawedzera zvishoma (inenge 5-10 ℃), iyo crystallinity inovandudzwa, uye yakakwirira tembiricha kuramba inowedzerwa (yakakodzera kupisa-inodzivirira bhodhoro preforms). |

| Kuvandudzwa kwemakemikari kuchena | Inobvisa zvakasara monomers (zvakadai se formaldehyde, acetaldehyde) uye oligomers (zviri kudonha kusvika pasi pe50 ppm), kusangana nemagiredhi ekudya. |

| Kubata zvinyoro zvinyoro | Solid-state reactions inodzivirira kupisa kweiyo oxidative degradation inokonzerwa nekunyungudika kwepamusoro-tembiricha uye inonyanya kukodzera kudzoreredza kwemhando yePET yakadzokororwa. |

| Process flexibility | Iyo viscosity yechigadzirwa chekupedzisira inogona kunyatso kudzorwa nekugadzirisa tembiricha, nguva uye vacuum degree, nekudaro kusangana nezvinodiwa zvakasiyana. |

Application

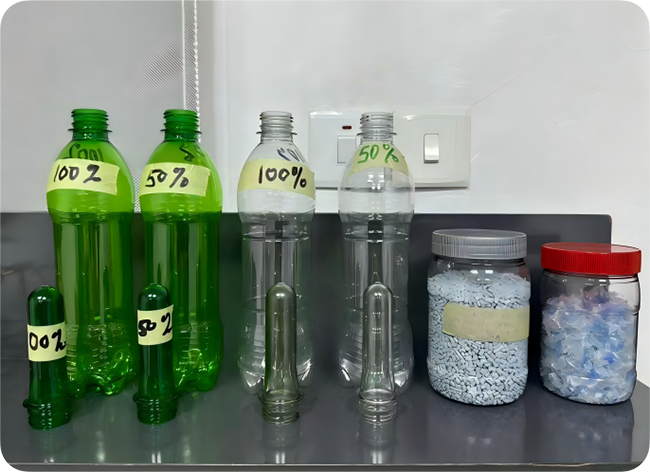

PET Preform

● Kugadzirwa kwebhodhoro repamusoro rakajeka:

Inovandudza kufanana kwePET viscosity, inoderedza kushushikana kwemuviri webhodhoro, inokodzera zvinwiwa zvecarbonated, midziyo yekushongedza, nezvimwe.

● Kugadzirwa kwebhodhoro rinodzivirira kupisa:

Kuburikidza neSSP, kukosha kweIV kunowedzerwa kusvika pamusoro pe0.85 dL/g, inokodzera mabhodhoro ezvinwiwa anopisa (sekurongedza kwetii, kofi).

Yakadzokororwa PET mhando yekusimudzira

● Kudzokorodza kwemabhodhoro akagadzirwazve:

Post-mutengi PET bhodhoro flakes inobatwa neyakasanganiswa maitiro e "kuomesa - yakasvibiswa - viscosity enhancement" kubvisa EG,Acetaldehyde, VOC uye kudzoreredza viscosity, kuvadzosera kune chikafu-giredhi kana maindasitiri-giredhi maapplication (senge fibers, mashizha).

● Kukosha kwehupfumi hwedenderedzwa:

Yakasanganiswa ne infrared drying (IRD) tekinoroji, "low-energy dehydration + inoshanda viscosity enhancement" inowanikwa kukurudzira yakavharwa-loop kudzokororwa kwePET.

Injiniya mapurasitiki emunda

● Kugadzirira kwePET yepamusoro-soro:

Kugadzirwa kwepamusoro-viscosity PET (IV> 1.0 dL/g) kuti ishandiswe muzvikamu zvemotokari (zvakadai semagiya, mabearings), dzimba dzemagetsi nemagetsi, nezvimwewo, kutsiva zvechinyakare engineering mapurasitiki.