Infrared Rotary Dryer + SSP system

Solid-phase polymerization (SSP) ndiye ukadaulo wofunikira pakukwaniritsa "kukweza bwino" komanso "kubwezeretsanso zobiriwira" mumndandanda wamakampani a PET.

LIANDA MACHINERY imaphatikizana kwambiriINFRARED ROTARY DRYER yokhala ndi dongosolo la SSPkupanga njira yophatikizira ya "Kuchotsa chinyezi moyenera - Kuwonjezeka kwamphamvu kokwanira - Kugwiritsira ntchito kochepa". Izi zimathandizira kwambiri mawonekedwe a rPET, kukhazikika kwamafuta komanso kuyera kwamankhwala. Ukadaulo uwu umachita gawo losasinthika mumndandanda wamakampani a PET (makamaka kubwezereranso kwapamwamba komanso kupanga kwapamwamba kwambiri).

Ngati mukufuna kudziwa ndondomeko yeniyeni kapena kasinthidwe ka zida, chonde lemberani Lianda Machinery kuti mupeze mayankho aukadaulo

Pre-processing Stage

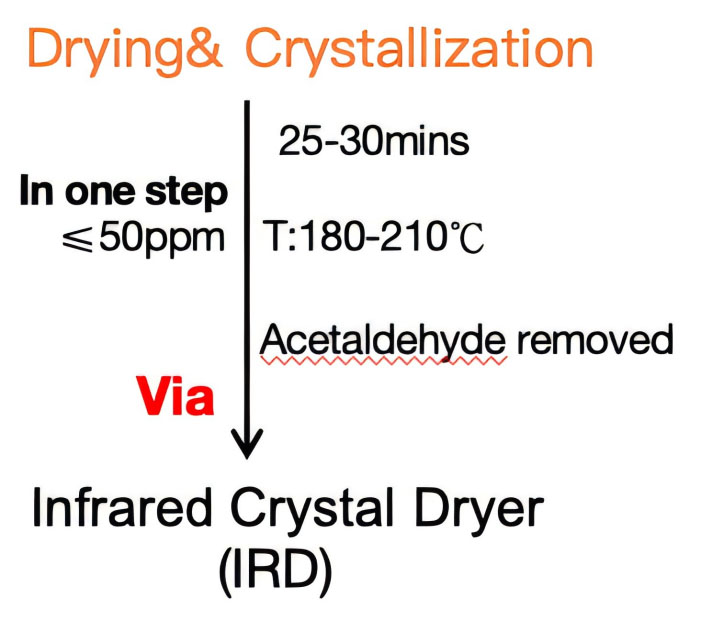

Kuyanika: PET ndi hygroscopic ndipo imayenera kuchotsedwa ndi IRD (Pambuyo pa IRD, PET yomaliza chinyezi ≤ 50 ppm) kupewa hydrolysis ndi kuwonongeka pa kutentha kwakukulu.

Crystallization: Ma pellets a PET amawunikiridwa ndi IRD (digiri ya crystallization ili pafupifupi 30-40%) kuti ateteze ma pellets a PET kuti asamamatire kapena kusungunuka pa kutentha kotsatira, pomwe akupereka malo olimba a polycondensation reaction.

Solid-phase Polycondensation Reaction Stage

➢ Zoyenera kuchita:

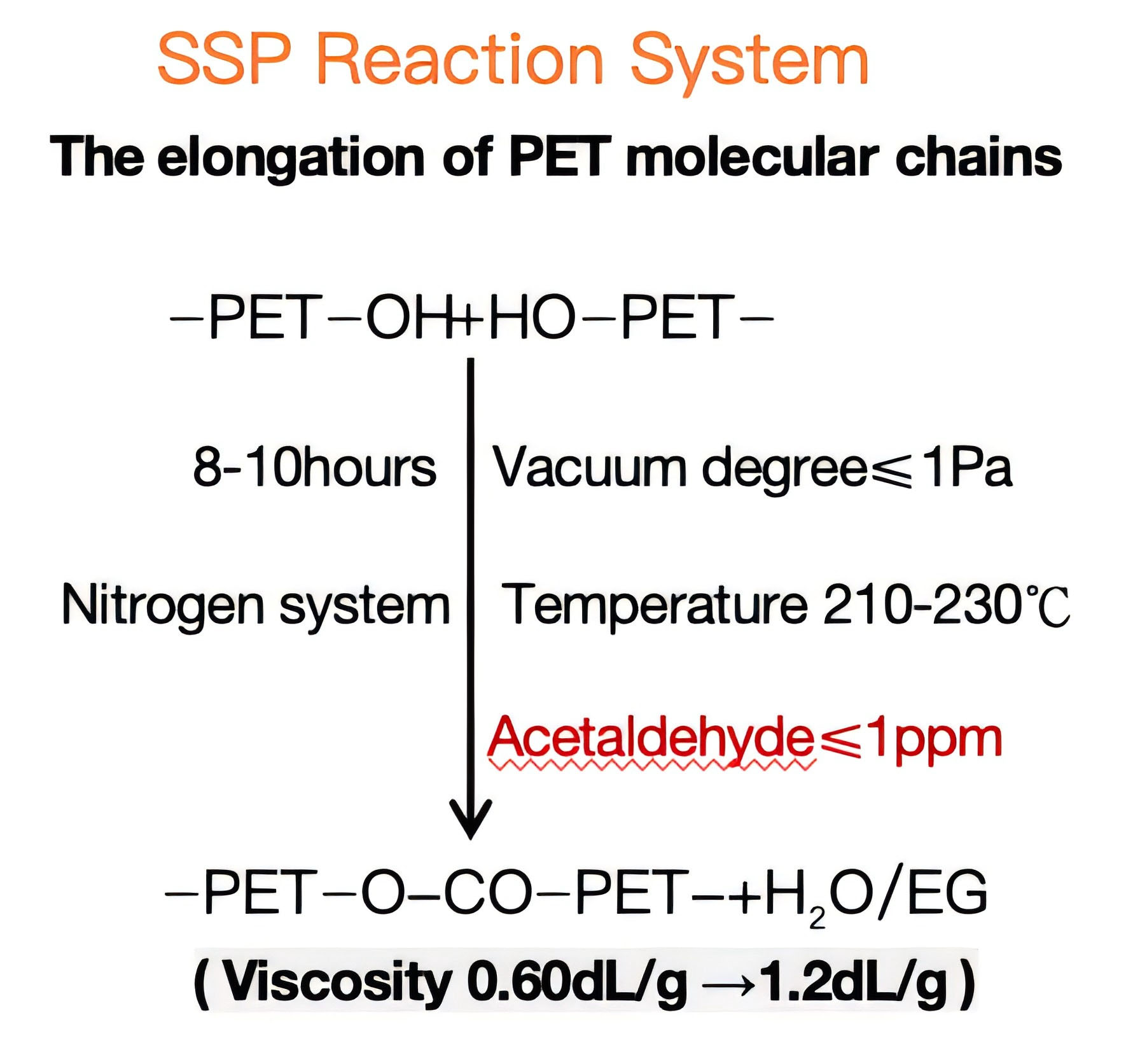

Kutentha: kumayendetsedwa pa 200-240 ℃ (otsika kuposa PET yosungunuka 250-260 ℃, khalani olimba).

Vacuum/inert gas flow: nayitrogeni imayambitsidwa ndipo vacuum imakokedwa kuti ichotse zomwe zimachitika ndi ethylene glycol (EG) ndikulimbikitsa momwe polycondensation imayendera bwino.

➢ Chemical reaction:

Hydroxyl (-OH) ndi carboxyl (-COOH) kumapeto kwa PET molekyulu ya PET amakumana ndi condensation reaction kuti apange ester bond (-COO-), pamene akutulutsa ethylene glycol (EG), kotero kuti unyolo wa maselo ukupitirizabe kukula ndipo kulemera kwa maselo (intrinsic viscosity IV) kumawonjezeka pang'onopang'ono.

Lianda Machinery integrates infuraredi kuyanika (IRD) ndi dongosolo SSP, mofulumira ndi wogawana kutentha zinthu kudzera infuraredi kunyezimira, kufupikitsa pretreatment nthawi, ndi optimizes misa kutengerapo Mwachangu mu olimba gawo anachita, kotero kuti dongosolo lonse ali ndi makhalidwe a dzuwa mkulu ndi kupulumutsa mphamvu, lalikulu processing mphamvu, ndi mkulu kukhazikika kwa mankhwala, amene makamaka oyenera zobwezerezedwanso apamwamba PET kupanga.

LIANDA MACHINERY imaphatikiza chowumitsira kristalo cha infrared (IRD) ndi dongosolo la SSP, lomwe limagwiritsa ntchito mafunde a infrared kuti litenthetse zinthu mwachangu komanso molingana, kufupikitsa nthawi yachidziwitso chisanachitike, ndikuwongolera kusuntha kwa misa mu gawo lolimba, ndikupanga dongosolo lonselo kukhala lopanda mphamvu kwambiri, lokhala ndi mphamvu yayikulu yopangira komanso kukhazikika kwazinthu zambiri. Ndizoyenera makamaka kupanga zazikulu zapamwamba za PET zobwezerezedwanso.

Ngati mukufuna zambiri zaukadaulo kapena mayankho osinthidwa makonda, mutha kulumikizana ndi Lianda Machinery kuti akuthandizeni

Kuphatikiza ndi ukadaulo wowumitsa wa infrared, imazindikira kuphatikizika kwa "decontaminated + drying + viscosity enhancement", kulimbikitsa kukonzanso kotseka kwa PET.

Kuphatikiza ndi ukadaulo wowumitsa wa infrared, imazindikira kuphatikizika kwa "decontaminated + drying + viscosity enhancement", kulimbikitsa kukonzanso kotseka kwa PET.

| Ubwino | Magwiridwe Mwapadera |

| Kulemera kwa mamolekyulu | The intrinsic viscosity (IV) imachulukitsidwa kwambiri ndipo mphamvu zamakina (mphamvu zamakina, zotanuka modulus) zimasinthidwa ndi 30-50%. |

| Kukhathamiritsa kokhazikika kwa kutentha | Malo osungunuka (Tm) amawonjezeka pang'ono (pafupifupi 5-10 ℃), crystallinity imapangidwa bwino, ndipo kukana kwa kutentha kwapamwamba kumalimbikitsidwa (koyenera kwa preforms ya botolo la kutentha). |

| Kupititsa patsogolo chiyero chamankhwala | Imachotsa ma monomers otsalira (monga formaldehyde, acetaldehyde) ndi oligomers (zokhutira zimatsika mpaka zosakwana 50 ppm), kukwaniritsa miyezo ya chakudya. |

| Kusamalira mofatsa katundu | Zochita zolimbitsa thupi zimapewa kuwonongeka kwa okosijeni chifukwa cha kusungunuka kwa kutentha kwambiri ndipo ndizofunikira makamaka pakubwezeretsanso kwabwino kwa PET yobwezerezedwanso. |

| Njira kusinthasintha | Kukhuthala kwa chinthu chomaliza kumatha kuyendetsedwa bwino ndikusintha kutentha, nthawi ndi digiri ya vacuum, motero kukwaniritsa zofunikira zosiyanasiyana. |

Kugwiritsa ntchito

PET Preform

● Kupanga mabotolo owonekera kwambiri:

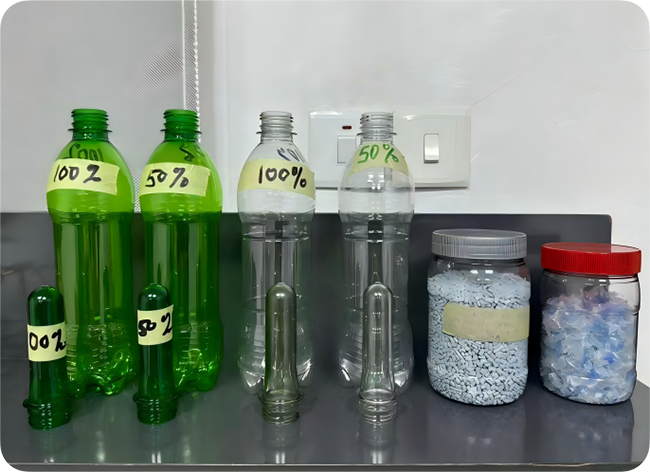

Imakulitsa kufanana kwa PET viscosity, imachepetsa kupsinjika kwa botolo la botolo, yoyenera zakumwa za carbonated, zodzikongoletsera, ndi zina.

● Kukula kwa botolo losagwira kutentha:

Kudzera pa SSP, mtengo wa IV umachulukitsidwa kufika pamwamba pa 0.85 dL/g, yoyenera mabotolo akumwa odzaza ndi kutentha (monga kulongedza kwa tiyi pompopompo, khofi).

Kusintha kwamtundu wa PET kobwezerezedwanso

● Kubwezeretsanso ma flakes a mabotolo obwezerezedwanso:

Ma flakes a botolo a PET amathandizidwa ndi njira yophatikizira ya "kuyanika - kuipitsidwa - kukulitsa kukhuthala" kuchotsa EG,Acetaldehyde, VOC ndi kubwezeretsa mamasukidwe akayendedwe, kuwabwezera ku kalasi ya chakudya kapena ntchito zamafakitale (monga ulusi, mapepala).

● Mtengo wachuma wozungulira:

Kuphatikizika ndi ukadaulo wa infrared drying (IRD), "kuchepa kwamphamvu kwamphamvu + komanso kuwongolera bwino kwa viscosity" kumatheka kulimbikitsa kubwezeretsanso kotseka kwa PET.

Engineering mapulasitiki munda

● Kukonzekera kwa PET kochita bwino kwambiri:

Kupanga mkulu-makamaka PET (IV> 1.0 dL/g) ntchito mbali magalimoto (monga magiya, mayendedwe), pakompyuta ndi nyumba zamagetsi, etc., m'malo pulasitiki zomangamanga chikhalidwe.