I-infrared Rotary Dryer + uhlelo lwe-SSP

I-Solid-phase polymerization (SSP) iwubuchwepheshe obuyinhloko bokuzuza "ukuthuthukiswa kwekhwalithi" kanye "nokuvuselela kabusha okuluhlaza" ochungechungeni lwemboni ye-PET.

I-LIANDA MACHINERY ihlanganisa ngokujulileINFRARED ROTARY DRYER ngohlelo lwe-SSPukwakha isixazululo esihlanganisiwe sokuthi "Ukukhipha umswakama osebenzayo - Ukwanda okuqondile kwe-viscosity - Ukusebenza kokusetshenziswa okuphansi". Lokhu kuthuthukisa kakhulu izakhiwo zomzimba ze-rPET, ukuzinza okushisayo kanye nokuhlanzeka kwamakhemikhali. Lobu buchwepheshe budlala indima engenakuthathelwa indawo ochungechungeni lwemboni ye-PET (ikakhulukazi ukukhiqizwa kabusha kwekhwalithi ephezulu kanye nokukhiqizwa komkhiqizo osebenza kahle kakhulu).

Uma udinga ukwazi imingcele ethile yenqubo noma ukucushwa kwemishini, sicela uthinte i-Lianda Machinery ukuze uthole izixazululo zobuchwepheshe ezenziwe ngokwezifiso.

Isiteji sokucubungula ngaphambilini

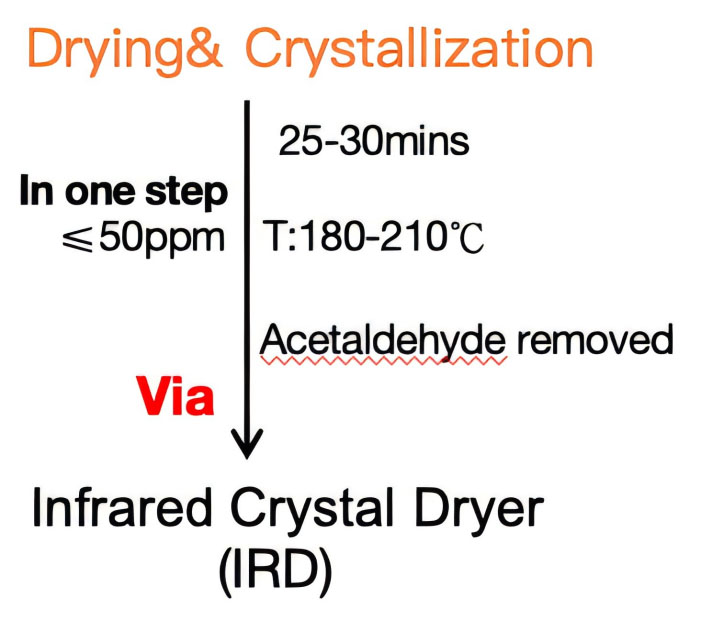

Ukomisa: I-PET i-hygroscopic futhi idinga ukususwa nge-IRD (Ngemva kwe-IRD, umswakama wokugcina we-PET ≤ 50 ppm) ukugwema i-hydrolysis kanye nokuwohloka emazingeni okushisa aphezulu.

I-Crystallization: Amapellets e-PET acwebezelwa yi-IRD (i-crystallization degree cishe i-30-40%) ukuvimbela amapellets e-PET ukuthi anganamatheli noma ancibilike emazingeni okushisa aphezulu alandelayo, kuyilapho ehlinzeka ngendawo eqinile eqinile yokusabela kwe-polycondensation.

Isigaba esiqinile se-Polycondensation Rection Stage

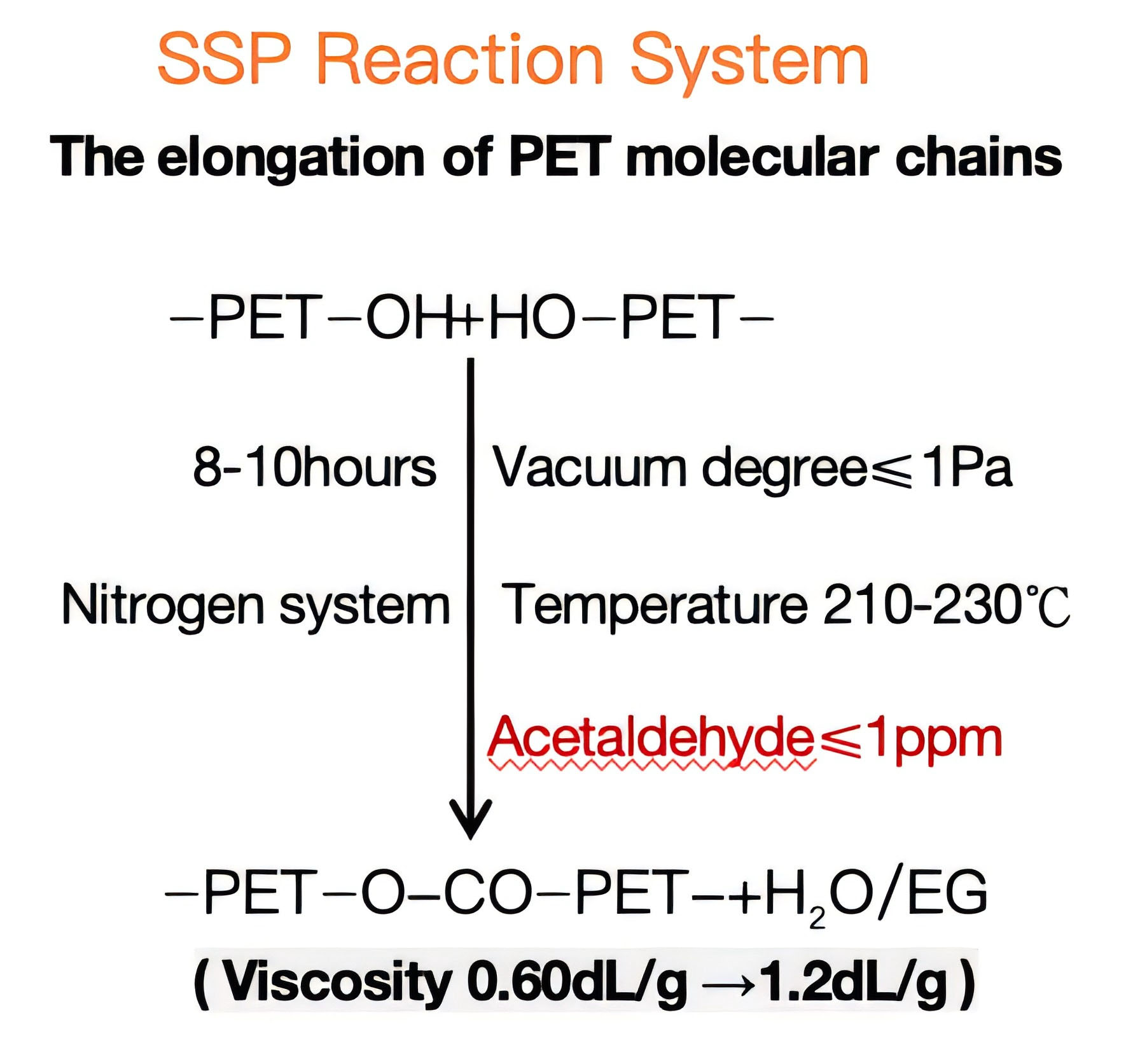

➢ Izimo zokusabela:

Izinga lokushisa: lilawulwa ku-200–240℃ (liphansi kunephoyinti lokuncibilika le-PET 250–260℃, hlala uqinile).

Ukugeleza kwe-vacuum/inert gas: kwethulwa i-nitrogen bese kudonswa i-vacuum ukuze kususwe ukusabela nge-ethylene glycol (EG) futhi kukhuthaze ukusabela kwe-polycondensation ohlangothini oluhle.

➢ Ukusabela kwamakhemikhali:

I-hydroxyl (-OH) ne-carboxyl (-COOH) ekugcineni kweketango le-PET yamangqamuzana ibhekana nokusabela kwe-condensation ukuze kwakhiwe i-ester bond (-COO-), kuyilapho ikhulula i-ethylene glycol (EG), ukuze uchungechunge lwamangqamuzana luqhubeke nokunwetshwa kanye nesisindo samangqamuzana (i-intrinsic viscosity IV) sikhula kancane kancane.

I-Lianda Machinery ihlanganisa ukomiswa kwe-infrared (IRD) nohlelo lwe-SSP, ishisisa ngokushesha futhi ngokulinganayo into esetshenziswayo ngemisebe ye-infrared, ifinyeze isikhathi sokwelashwa kwangaphambili, futhi ikhulise ukusebenza kahle kokudluliswa kwenqwaba ekuphenduleni kwesigaba esiqinile, ukuze lonke uhlelo lube nezici zokusebenza kahle kakhulu nokonga amandla, umthamo omkhulu wokucubungula, nokuzinza komkhiqizo ophezulu, ofaneleka ngokukhethekile ukukhiqizwa kwe-PET okuseqophelweni eliphezulu.

I-LIANDA MACHINERY ihlanganisa i-Infrared crystal dryer (IRD) nohlelo lwe-SSP, olusebenzisa igagasi le-infrared ukushisa izinto ngokushesha nangokulinganayo, lifinyeze isikhathi sangaphambi kokwelashwa, futhi lenze ukusebenza kahle kokudluliswa kwenqwaba ekuphenduleni kwesigaba esiqinile, okwenza lonke uhlelo luwonge kakhulu amandla, lunamandla amakhulu okucubungula kanye nokuzinza komkhiqizo ophezulu. Ifaneleka ngokukhethekile ukukhiqizwa kwekhwalithi ephezulu kwe-PET egaywe kabusha.

Uma udinga eminye imininingwane yobuchwepheshe noma izixazululo ezenziwe ngezifiso, ungaxhumana ne-Lianda Machinery ukuze uthole ukwesekwa kochwepheshe

Ngokuhambisana nobuchwepheshe bokomisa nge-infrared, ibona ukuhlanganiswa "kwe-decontaminated + drying + viscosity enhancement", okugqugquzela ukugaywa kabusha kwe-loop evaliwe kwe-PET.

Ngokuhambisana nobuchwepheshe bokomisa nge-infrared, ibona ukuhlanganiswa "kwe-decontaminated + drying + viscosity enhancement", okugqugquzela ukugaywa kabusha kwe-loop evaliwe kwe-PET.

| Inzuzo | Ukusebenza Okuthize |

| Ukwanda kwesisindo samangqamuzana | I-intrinsic viscosity (IV) yanda kakhulu futhi amandla emishini (amandla aqinile, i-elastic modulus) athuthukiswa ngama-30-50%. |

| Ukuthuthukisa ukuzinza kwe-thermal | Iphuzu elincibilikayo (Tm) linyuswe kancane (cishe ngo-5–10℃), ubucwebe buyathuthukiswa, futhi ukumelana nezinga lokushisa eliphezulu kuyathuthukiswa (okulungele amabhodlela avikela ukushisa). |

| Ukuhlanzeka kwamakhemikhali okuthuthukisiwe | Isusa ama-monomers ayinsalela (afana ne-formaldehyde, acetaldehyde) nama-oligomers (okuqukethwe kwehla kuze kube ngaphansi kuka-50 ppm), kuhlangatshezwane namazinga ebanga lokudla. |

| Izakhiwo zokuphatha ezinobumnene | Ukusabela kwesimo esiqinile kugwema ukuwohloka kwe-oxidative eshisayo okubangelwa ukuncibilika kwezinga lokushisa eliphezulu futhi kulungele ikakhulukazi ukubuyiselwa kwekhwalithi ye-PET egaywe kabusha. |

| Ukuvumelana nezimo | I-viscosity yomkhiqizo wokugcina ingalawulwa ngokunembile ngokulungisa izinga lokushisa, isikhathi kanye ne-vacuum degree, ngaleyo ndlela ihlangabezane nezidingo ezihlukahlukene. |

Isicelo

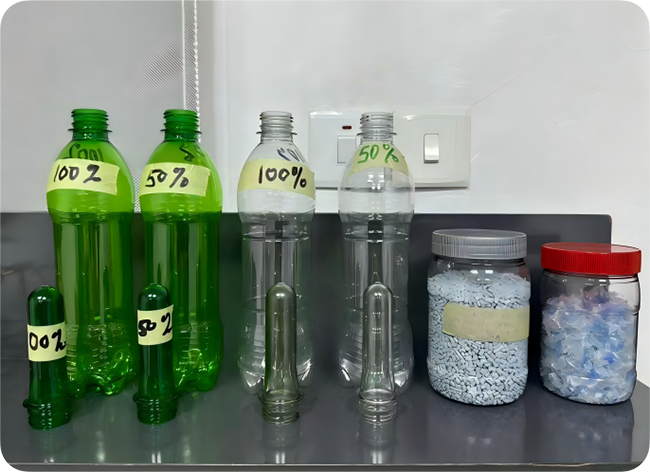

I-PET Preform

● Ukukhiqizwa kwamabhodlela angafihli okuphezulu:

Ithuthukisa ukufana kwe-PET viscosity, inciphisa ukuqhekeka kwengcindezi yomzimba webhodlela, ilungele iziphuzo ze-carbonated, iziqukathi zezimonyo, njll.

● Ukuthuthukiswa kwebhodlela elikwazi ukumelana nokushisa:

Nge-SSP, inani le-IV lenyuka libe ngaphezu kuka-0.85 dL/g, lilungele amabhodlela eziphuzo agcwele ukushisa (njengokupakisha itiye elisheshayo, ikhofi).

Ukuthuthukiswa kwekhwalithi ye-PET okugaywe kabusha

● Ukugaywa kabusha kwama-flakes amabhodlela agaywe kabusha:

Ama-flakes ebhodlela le-PET asetshenziswa ngemuva aphathwa ngenqubo edidiyelwe "yokomisa - ukungcoliswa - ukuthuthukiswa kwe-viscosity" ukuze kukhishwe i-EG,i-Acetaldehyde, i-VOC nokubuyisela i-viscosity, ukuwabuyisela ekusetshenzisweni kwebanga lokudla noma izinga lezimboni (njengemicu, amashidi).

● Inani lezomnotho eliyindilinga:

Kuhlanganiswe nobuchwepheshe be-infrared drying (IRD), "ukuphelelwa amandla kwamanzi aphansi + ukuthuthukiswa okusebenzayo kwe-viscosity" kufinyelelwa ukukhuthaza ukuvuselelwa kabusha kwe-loop evaliwe kwe-PET.

Inkambu yepulasitiki yobunjiniyela

● Ukulungiswa kwe-PET esebenza kahle kakhulu:

Ukukhiqizwa kwe-PET ene-viscosity ephezulu (IV>1.0 dL/g) ukuze isetshenziswe ezingxenyeni zezimoto (njengamagiya, ama-bearings), izindlu zikagesi nezikagesi, njll., ukuze kuthathelwe indawo amapulasitiki obunjiniyela bendabuko.