I-Infrared Rotary Dryer + inkqubo ye-SSP

I-Solid-phase polymerization (SSP) yitekhnoloji ephambili yokufezekisa "ukuphuculwa komgangatho" kunye "nohlaziyo oluhlaza" kwikhonkco leshishini le-PET.

UMSHISHINI we-LIANDA udibanisa ngokunzuluI-INFRARED ROTARY DRYER ngenkqubo ye-SSPukwenza isisombululo esidibeneyo "Ukususa umswakama osebenzayo - Ukunyuka kwe-viscosity echanekileyo - Ukusebenza kokusetyenziswa okuphantsi". Oku kuphucula kakhulu iipropathi zomzimba ze-rPET, ukuzinza kwe-thermal kunye nokucoceka kweekhemikhali. Le teknoloji idlala indima engenakuphinda ithathelwe indawo kwitsheyini leshishini le-PET (ingakumbi ukurisayikilishwa komgangatho ophezulu kunye nokuveliswa kwemveliso yokusebenza okuphezulu).

Ukuba ufuna ukwazi iparameters zenkqubo ethile okanye uqwalaselo lwezixhobo, nceda uqhagamshelane noLianda Machinery ukufumana izisombululo zobugcisa ezilungiselelweyo.

Inqanaba lokulungisa kwangaphambili

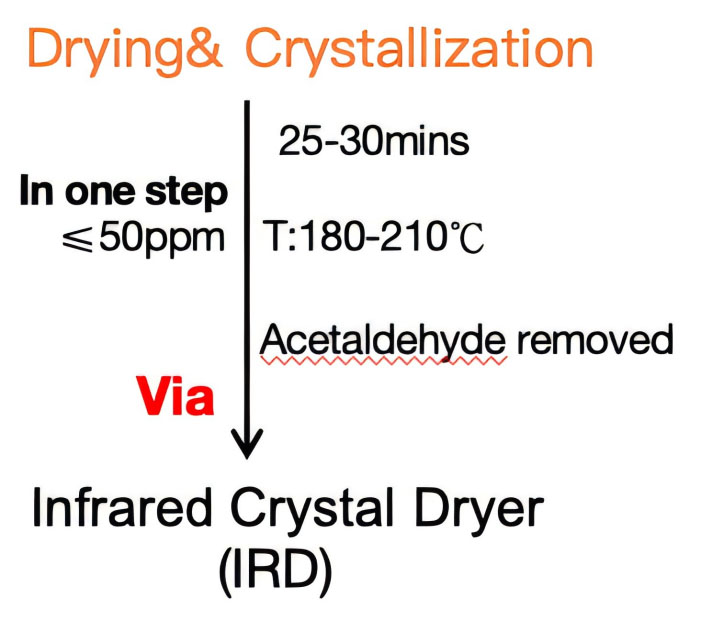

Ukomisa: I-PET i-hygroscopic kwaye kufuneka isuswe yi-IRD (Emva kwe-IRD, i-PET umswakama wokugqibela ≤ 50 ppm) ukuphepha i-hydrolysis kunye nokuthotywa kwamaqondo aphezulu.

I-Crystallization: Iipelisi ze-PET zixutywe yi-IRD (i-crystallization degree malunga ne-30-40%) ukukhusela iipelisi ze-PET ukuba zinganamatheli okanye zinyibilike kumaqondo aphezulu alandelayo, ngelixa zibonelela ngendawo ezinzileyo eqinileyo yokuphendula i-polycondensation.

Isigaba esiqinileyo sePolycondensation Reaction Stage

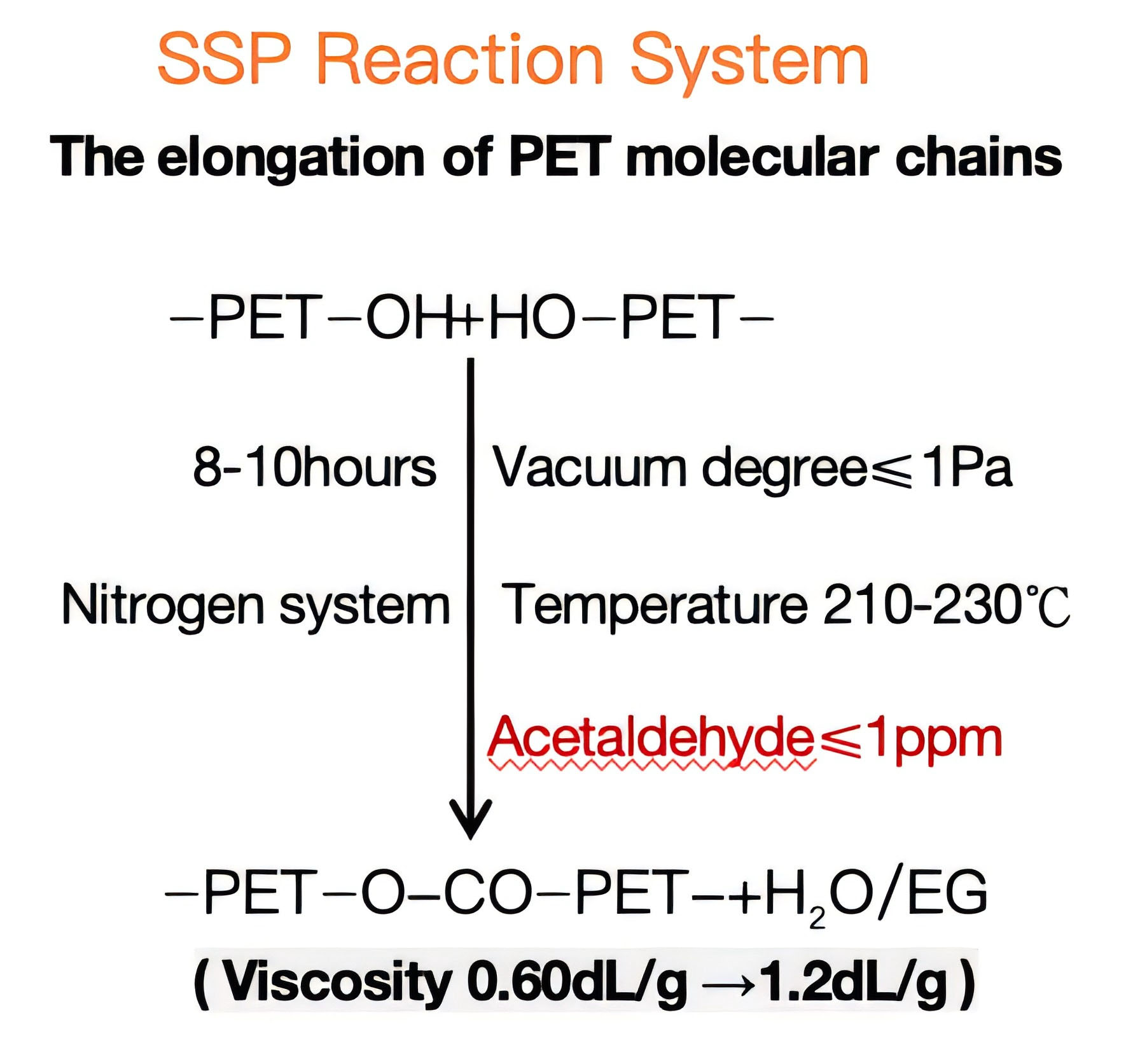

➢ Imiqathango yokusabela:

Iqondo lobushushu: ilawulwa ku-200–240℃ (ngaphantsi kune-PET melting point 250–260℃, hlala uqinile).

I-vacuum / i-inert gas flow flow: i-nitrogen iyaziswa kwaye i-vacuum itsalwa ukususa i-reaction byproduct ethylene glycol (EG) kwaye ikhuthaze ukuphendula kwe-polycondensation kwicala elihle.

➢ Ukusabela kwemichiza:

I-hydroxyl (-OH) kunye ne-carboxyl (-COOH) ekupheleni kwe-PET i-molecular chain ifumana i-condensation reaction ukuze yenze i-ester bond (-COO-), ngelixa ikhulula i-ethylene glycol (EG), ukwenzela ukuba i-molecular chain iqhubeke nokwandisa kwaye ubunzima be-molecular (intrinsic viscosity IV) bukhula ngokuthe ngcembe.

Umatshini weLianda udibanisa ukomiswa kwe-infrared (IRD) kunye nenkqubo ye-SSP, ngokukhawuleza nangokulinganayo ukufudumeza izinto ngemitha ye-infrared, kunciphisa ixesha lokulungiswa kwangaphambili, kunye nokwandisa ukusebenza kakuhle kokudluliselwa kobuninzi kwi-reaction yesigaba esiqinileyo, ukuze yonke inkqubo ibe neempawu zokusebenza okuphezulu kunye nokonga amandla, umthamo omkhulu wokusetyenzwa, kunye nokuzinza kwemveliso ephezulu, elungele ngokukodwa ukuveliswa komgangatho ophezulu we-PET.

I-LIANDA MACHINERY idibanisa i-Infrared crystal dryer (IRD) kunye nenkqubo ye-SSP, esebenzisa i-wave ye-infrared ukufudumala ngokukhawuleza kunye nokutshisa izinto eziphathekayo, ukunciphisa ixesha lonyango lwangaphambili, kunye nokwandisa ukusebenza kakuhle kokudluliselwa kobuninzi kwi-reaction yesigaba esiqinileyo, okwenza yonke inkqubo isebenzise amandla amaninzi, kunye nomthamo omkhulu wokucubungula kunye nokuzinza kwemveliso ephezulu. Ifaneleke ngokukodwa ukuveliswa komgangatho ophezulu we-PET ehlaziyiweyo.

Ukuba ufuna iinkcukacha ezongezelelekileyo zobugcisa okanye izisombululo ezilungiselelwe wena, ungaqhagamshelana noLianda Machinery ngenkxaso yobungcali

Ngokudibanisa ne-infrared drying technology, iqonda ukudityaniswa kwe-"decontaminated + drying + viscosity enhancement", ukukhuthaza ukuphinda kusetyenziswe i-loop evaliweyo ye-PET.

Ngokudibanisa ne-infrared drying technology, iqonda ukudityaniswa kwe-"decontaminated + drying + viscosity enhancement", ukukhuthaza ukuphinda kusetyenziswe i-loop evaliweyo ye-PET.

| Inzuzo | Ukusebenza ngokuthe ngqo |

| Ukwanda kobunzima bemolekyuli | I-intrinsic viscosity (IV) yanda kakhulu kwaye amandla omatshini (amandla anqabileyo, i-elastic modulus) aphuculwe ngama-30-50%. |

| Ukulungiswa kozinzo lwe-Thermal | Iqondo lokunyibilika (Tm) linyuswe kancinci (malunga ne-5-10 ℃), i-crystallinity iphuculwe, kwaye ukuchasana nokushisa okuphezulu kuphuculwe (kufanelekile kwi-preforms yebhotile ekwazi ukumelana nobushushu). |

| Ukuphucula ukucoceka kweekhemikhali | Isusa iimonomers ezishiyekileyo (ezifana ne-formaldehyde, i-acetaldehyde) kunye ne-oligomers (umxholo wehla ukuya ngaphantsi kwe-50 ppm), ukuhlangabezana nemigangatho yebakala lokutya. |

| Iimpawu zokuphatha ngobumnene | Iimpendulo ze-Solid-state zithintela ukuthotywa kwe-thermal oxidative okubangelwa kukunyibilika kobushushu obuphezulu kwaye zifaneleke ngokukodwa ukubuyisela umgangatho we-PET ehlaziyiweyo. |

| Inkqubo yokuguquguquka | I-viscosity yemveliso yokugqibela inokulawulwa ngokuchanekileyo ngokulungelelanisa ubushushu, ixesha kunye neqondo le-vacuum, ngoko ke ukuhlangabezana neemfuno ezahlukeneyo. |

Isicelo

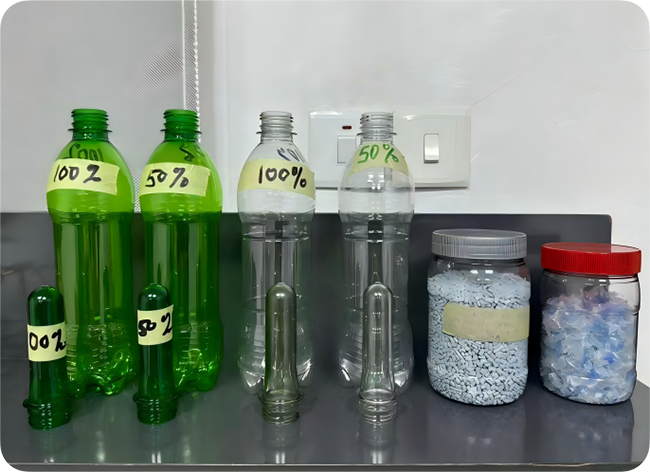

I-PET Preform

● Ukuveliswa kwebhotile ecacileyo ephezulu:

Ukuphucula ukufana kwe-PET viscosity, kunciphisa uxinzelelo lomzimba webhotile, ulungele iziselo ze-carbonated, izitya zokuthambisa, njl.

● Uphuhliso lwebhotile ekwaziyo ukumelana nobushushu:

Nge-SSP, ixabiso le-IV linyuswe ngaphezu kwe-0.85 dL / g, ifanelekile kwiibhotile zesiselo ezishushu (ezifana nokupakishwa kweti esheshayo, ikofu).

Uphuculo lomgangatho we-PET osetyenzisiweyo

● Ukurisayikilishwa kweeflake zebhotile ezisetyenzisiweyo:

Iiflake zebhotile ze-PET ze-Post-consumer ziphathwa ngenkqubo edibeneyo "yokomisa - i-decontaminated - i-viscosity enhancement" ukususa i-EG,i-Acetaldehyde, i-VOC kunye nokubuyisela i-viscosity, ukuyibuyisela kwi-inkqubo yokutya okanye kwi-industrial-grade applications (ezifana neefibers, amaphepha).

● Ixabiso lezoqoqosho kwisetyhula:

Idityaniswe netekhnoloji ye-infrared drying (IRD), "ukuphelelwa amandla okuncinci + amandla aphantsi + ukuphuculwa okusebenzayo kwe-viscosity" kuphunyeziwe ukukhuthaza ukuphinda kusetyenziswe i-loop evaliweyo ye-PET.

Intsimi yeeplastiki zobunjineli

● Amalungiselelo e-PET akumgangatho ophezulu:

Ukuveliswa kwe-PET ephezulu-viscosity (IV> 1.0 dL / g) yokusetyenziswa kwiindawo zemoto (ezifana neegiya, iibheringi), izindlu zombane kunye nombane, njl., Ukutshintsha iiplastiki zobunjineli bendabuko.