Infrared Rotary Drer + Sistemụ SSP

Polymerization siri ike (SSP) bụ teknụzụ bụ isi maka inweta “nkwalite ogo” yana “nrụgharị akwụkwọ ndụ akwụkwọ ndụ” na yinye ụlọ ọrụ PET.

LIANDA MACHINERY na-ejikọta nke ọmaINFRARED ROTARY DRYER nwere sistemu SSPna-etolite ihe agbakwunyere ngwọta nke "Ere nke ọma mmiri wepụ - Kpọmkwem viscosity mmụba - ala-eri ọrụ". Nke a na-eme ka njirimara anụ ahụ rPET dịkwuo mma, nkwụsi ike ọkụ na ịdị ọcha kemịkal. Nkà na ụzụ a na-arụ ọrụ na-enweghị atụ na agbụ ụlọ ọrụ PET (karịsịa imegharị ihe dị elu na mmepụta ngwaahịa dị elu).

Ọ bụrụ na ịchọrọ ịmata usoro usoro ma ọ bụ nhazi akụrụngwa, biko kpọtụrụ Lianda Machinery iji nweta ngwọta ọrụ aka ahaziri ahazi

Oge nhazi ụzọ

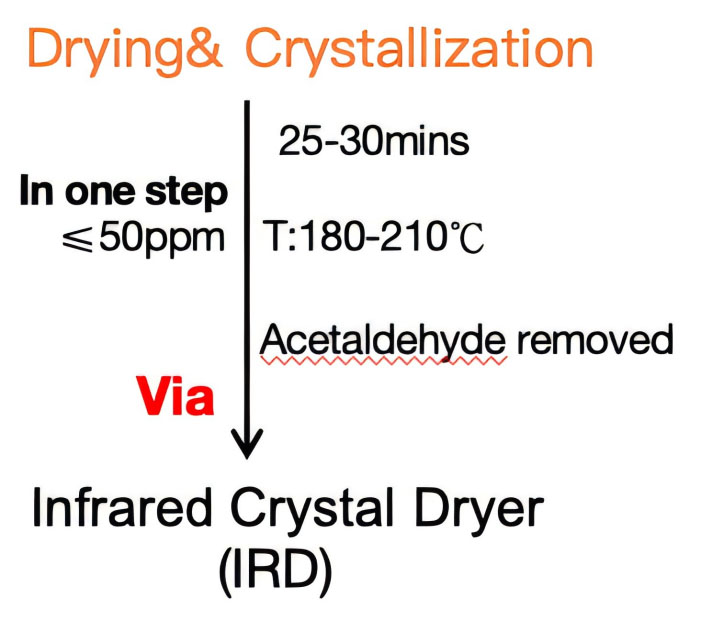

ihicha: PET bụ hygroscopic na ọ dị mkpa ka IRD wepụ ya (Mgbe IRD gasịrị, mmiri ikpeazụ PET ≤ 50 ppm) iji zere hydrolysis na mmebi na oke okpomọkụ.

Crystallization: PET pellets bụ crystallized site IRD (crystallization ogo bụ banyere 30-40%) iji gbochie PET pellets ịrapara ma ọ bụ gbazee na sochiri elu okpomọkụ, na-enye ebe siri ike siri ike maka polycondensation mmeghachi omume.

Usoro mmeghachi omume polycondensation siri ike

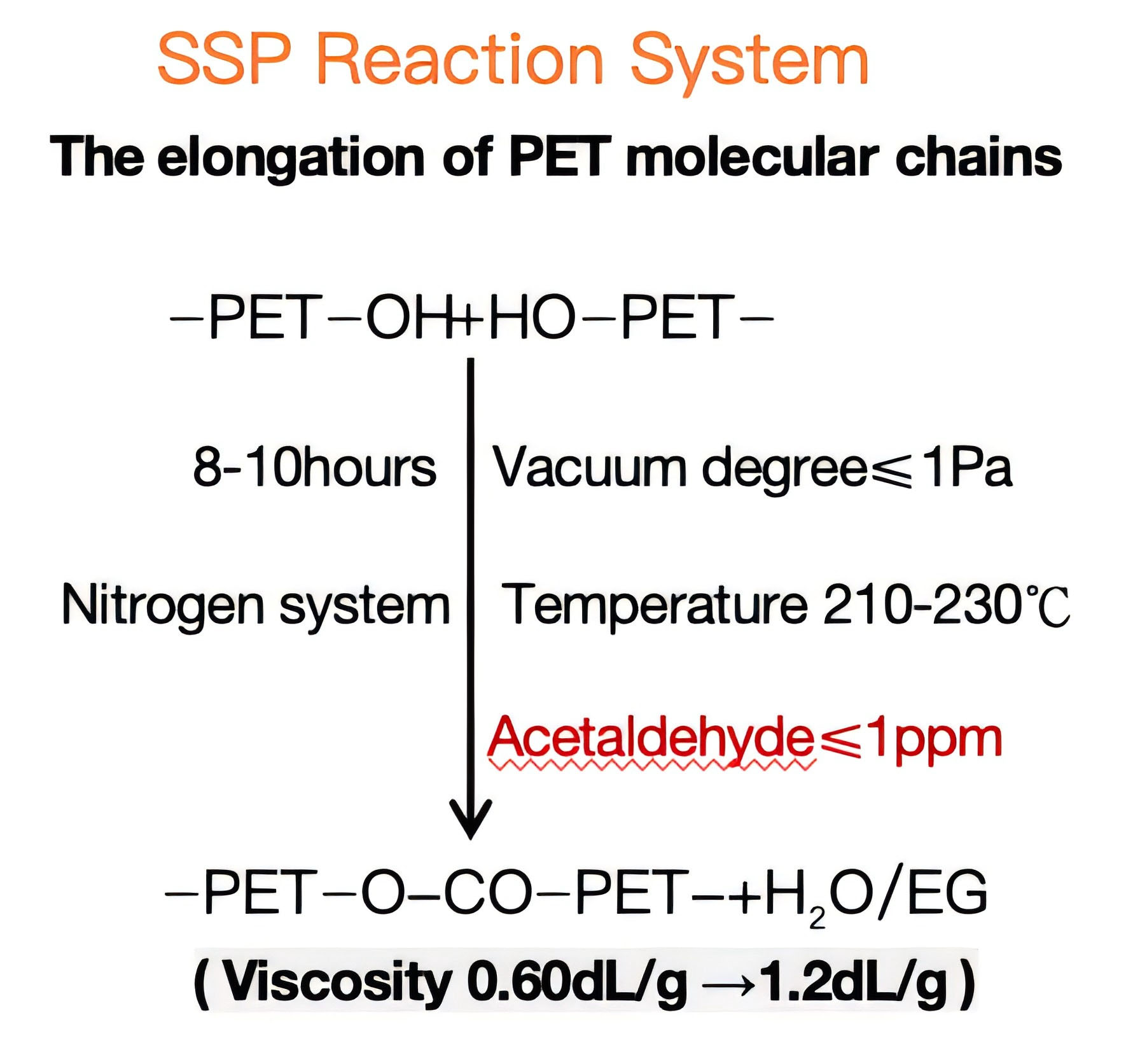

➢ Ọnọdụ mmeghachi omume:

Okpomọkụ: na-achịkwa na 200-240 ℃ (dị ala karịa PET agbaze ebe 250-260 ℃, na-esi ike).

Vacuum/inert gas eruba: ewebata nitrogen na oghere na-adọta iji wepụ mmeghachi omume siteproduct ethylene glycol (EG) ma kwalite mmeghachi omume polycondensation n'ụzọ dị mma.

➢ mmeghachi omume kemịkalụ:

Hydroxyl (-OH) na carboxyl (-COOH) na njedebe nke agbụ molecular PET na-enweta mmeghachi omume condensation iji mepụta njikọ ester (-COO-), ebe ha na-ahapụ ethylene glycol (EG), nke mere na agbụ molecular na-aga n'ihu na-agbatị na ịdị arọ molecular (intrinsic viscosity IV) ji nwayọọ nwayọọ na-abawanye.

Lianda Machinery integrates infrared ihicha (IRD) na SSP usoro, ngwa ngwa na evenly heats ihe site infrared ụzarị, shortens na pretreatment oge, na optimizes na uka nyefe arụmọrụ na siri ike na-adọ mmeghachi omume, nke mere na dum usoro nwere àgwà nke elu arụmọrụ na ike ịzọpụta, nnukwu nhazi ikike, na elu ngwaahịa kwụsie ike, nke bụ karịsịa nke kwesịrị ekwesị mmepụta nke PET mmepụta nke dị elu.

LIANDA MACHINERY jikọtara Infrared crystal dryer (IRD) na usoro SSP, nke na-eji infrared ebili mmiri na-ekpo ọkụ ngwa ngwa na ọbụna kpochaa ihe ahụ, na-ebelata oge ọgwụgwọ tupu oge ahụ, ma na-ebuli ọrụ nnyefe nke oke na mmeghachi omume siri ike, na-eme ka usoro ahụ dum dị ike na-arụ ọrụ nke ọma, na nnukwu ikike nhazi na nkwụsi ike ngwaahịa dị elu. Ọ dabara nke ọma maka nnukwu mmepụta dị elu nke PET megharịrị.

Ọ bụrụ na ịchọrọ nkọwa teknụzụ ọzọ ma ọ bụ ihe ngwọta ahaziri, ị nwere ike ịkpọtụrụ Lianda Machinery maka nkwado ọkachamara

Na mgbakwunye na teknụzụ ihicha infrared, ọ na-achọpụta njikọta nke "mmebi ihie + ihicha + viscosity nkwalite", na-akwalite mmegharịgharị mechiri emechi nke PET.

Na mgbakwunye na teknụzụ ihicha infrared, ọ na-achọpụta njikọta nke "mmebi ihie + ihicha + viscosity nkwalite", na-akwalite mmegharịgharị mechiri emechi nke PET.

| Uru | Arụmọrụ akọwapụtara |

| Mmụba arọ molekụla | Viscosity intrinsic (IV) na-abawanye nke ukwuu yana ike igwe (ike tensile, modulus na-agbanwe) na-emeziwanye site na 30-50%. |

| Nkwalite nkwụsi ike nke okpomọkụ | Ebe mgbaze (Tm) na-abawanye ntakịrị (ihe dị ka 5-10 ℃), kristal na-eme ka ọ dịkwuo mma, a na-eme ka nguzogide okpomọkụ dị elu (dabara maka preforms karama na-eguzogide okpomọkụ). |

| Ọcha kemịkalụ emelitere | Na-ewepụ monomers fọdụrụnụ (dị ka formaldehyde, acetaldehyde) na oligomers (ọdịnaya na-agbada ruo ihe na-erughị 50 ppm), na-ezute ụkpụrụ ọkwa nri. |

| Njirimara njikwa dị nro | Mmeghachi omume nke steeti siri ike na-ezere mmebi oxidative thermal nke na-agbaze okpomọkụ dị elu ma dabara adaba maka mweghachi nke ọma nke PET megharịrị. |

| Usoro mgbanwe | Enwere ike ịchịkwa viscosity nke ngwaahịa ikpeazụ nke ọma site n'ịgbanwe ọnọdụ okpomọkụ, oge na ogo agụụ, si otú a na-egbo mkpa dị iche iche. |

Ngwa

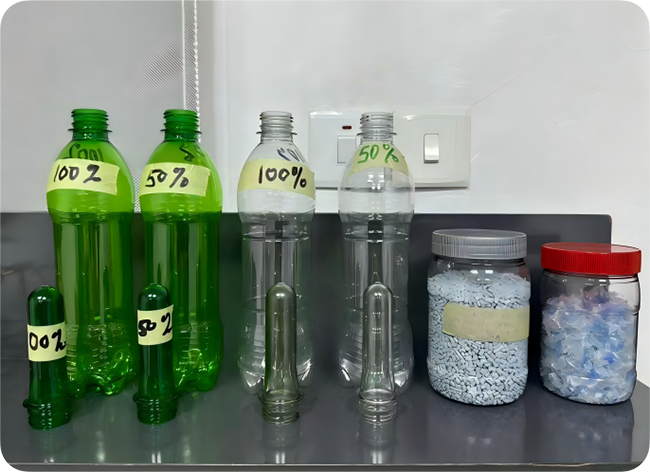

PET Preform

● Mmepụta karama nghọta dị elu:

Na-eme ka ịdị n'otu nke viscosity PET dịkwuo mma, na-ebelata nchekasị nke ahụ karama, dabara maka ihe ọṅụṅụ carbonated, ihe ịchọ mma, wdg.

● Mmepe karama na-eguzogide okpomọkụ:

Site na SSP, ọnụ ahịa IV na-abawanye n'elu 0.85 dL / g, dabara maka karama ihe ọṅụṅụ na-ekpo ọkụ (dị ka nkwakọ ngwaahịa maka tii ngwa ngwa, kọfị).

Nkwalite ogo PET emegharịrị

● Mwegharị nke flakes karama emegharịrị:

A na-emeso flakes karama PET mgbe ndị na-azụ ahịa na usoro agbakwunyere nke "ihicha - decontaminated - nkwalite viscosity" iji wepụ EG,Acetaldehyde, VOC ma weghachi viscosity, na-eweghachi ha na ọkwa nri ma ọ bụ ngwa ụlọ ọrụ mmepụta ihe (dị ka eriri, mpempe akwụkwọ).

● Uru akụ na ụba okirikiri:

Ejikọtara ya na teknụzụ ihicha infrared (IRD), a na-enweta "mmiri mmiri na-adịghị ike dị ala + nkwalite viscosity dị mma" iji kwalite imegharịgharị nke PET mechiri emechi.

Ngalaba plastik injinia

● Nkwadebe PET dị elu:

Mmepụta nke elu viscosity PET (IV> 1.0 dL / g) maka ojiji na akụkụ ụgbọ ala (dị ka gia, bearings), ụlọ eletrọnịkị na eletriki, wdg, iji dochie plastik injinia ọdịnala.