Infrared Rotary Dryer + SSP system

Solid-theem polymerization (SSP) yog lub thev naus laus zis tseem ceeb rau kev ua tiav "kev txhim kho zoo" thiab "ntsuab rov ua dua tshiab" hauv PET kev lag luam saw.

LANDA MACHINERY sib sib zog nqusINFRARED ROTARY DRYER nrog SSP systemlos tsim ib qho kev daws teeb meem ntawm "Nyob noo noo tshem tawm - Precise viscosity nce - Tsawg-kev lag luam". Qhov no txhim kho rPET lub cev muaj zog, thermal stability thiab tshuaj purity. Cov thev naus laus zis no ua lub luag haujlwm tsis tuaj yeem hloov pauv hauv PET kev lag luam saw (tshwj xeeb tshaj yog cov khoom siv rov ua dua tshiab thiab cov khoom ua tau zoo).

Yog tias koj xav paub txog cov txheej txheem tshwj xeeb lossis kev teeb tsa cov khoom siv, thov hu rau Lianda Machinery kom tau txais cov kev daws teeb meem kho mob.

Pre-processing Theem

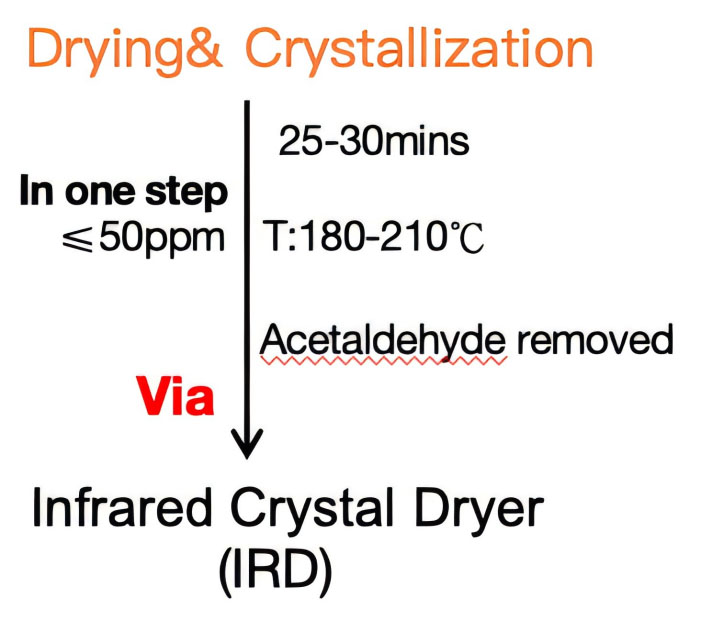

Kev ziab: PET yog hygroscopic thiab yuav tsum tau muab tshem tawm los ntawm IRD (Tom qab IRD, PET zaum kawg ya raws ≤ 50 ppm) kom tsis txhob hydrolysis thiab degradation ntawm qhov kub thiab txias.

Crystallization: PET pellets yog crystallized los ntawm IRD (crystallization degree yog hais txog 30-40%) los tiv thaiv PET pellets los ntawm sticking los yog melting tom qab kub kub, thaum muab ib tug ruaj khov ib puag ncig rau polycondensation tshuaj tiv thaiv.

Solid-phase Polycondensation Reaction Stage

➢ Cov xwm txheej tshwm sim:

Kub: tswj ntawm 200-240 ℃ (tsawg dua PET melting point 250-260 ℃, kom ruaj khov).

Nqus / inert gas flow: nitrogen yog qhia thiab nqus tau los tshem tawm cov tshuaj tiv thaiv byproduct ethylene glycol (EG) thiab txhawb cov tshuaj tiv thaiv polycondensation nyob rau hauv txoj kev zoo.

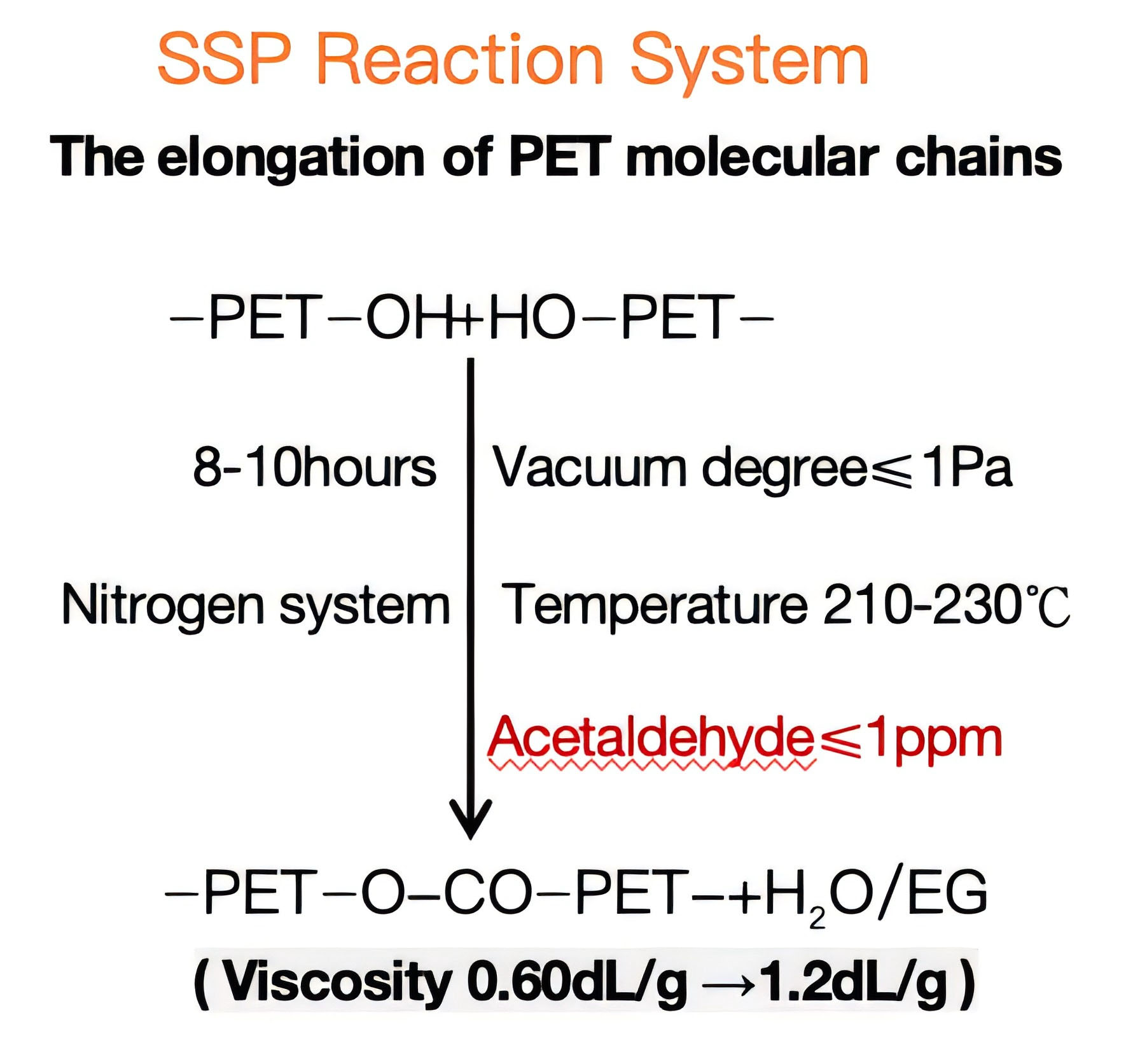

➢ Tshuaj tiv thaiv:

Cov hydroxyl (-OH) thiab carboxyl (-COOH) tom kawg ntawm PET molecular saw tau txais cov tshuaj tiv thaiv condensation los tsim ib daim ntawv cog lus ester (-COO-), thaum tso tawm ethylene glycol (EG), kom cov saw molecular txuas ntxiv mus thiab qhov hnyav molecular (intrinsic viscosity IV) maj mam nce.

Lianda Machinery integrates infrared drying (IRD) nrog rau SSP system, sai thiab sib npaug heats cov khoom los ntawm infrared rays, shortens lub pretreatment lub sij hawm, thiab optimizes huab hwm coj hloov efficiency nyob rau hauv cov khoom theem cov tshuaj tiv thaiv, kom tag nrho cov system muaj cov yam ntxwv ntawm high efficiency thiab lub zog txuag, loj ua peev xwm, thiab cov khoom siab stability, uas yog tshwj xeeb tshaj yog haum rau cov high-quality PET.

LIANDA MACHINERY integrates Infrared siv lead ua tshuab ziab khaub ncaws (IRD) nrog SSP system, uas siv infrared nthwv dej kom sai thiab sib npaug ntawm cov khoom cua sov, ua kom lub sijhawm kho ua ntej, thiab ua kom zoo dua qhov kev hloov pauv huab cua hauv cov tshuaj tiv thaiv theem, ua rau tag nrho cov kab ke muaj zog heev, nrog rau kev ua haujlwm loj thiab cov khoom lag luam siab. Nws yog tshwj xeeb tshaj yog haum rau loj-scale high-zoo zus tau tej cov PET recycled.

Yog tias koj xav tau cov lus qhia ntxiv lossis cov kev daws teeb meem, koj tuaj yeem tiv tauj Lianda Machinery rau kev txhawb nqa

Ua ke nrog infrared tshuab ziab khaub ncaws, nws paub txog kev sib koom ua ke ntawm "decontaminated + drying + viscosity li", txhawb kev kaw-voj rov ua dua ntawm PET.

Ua ke nrog infrared tshuab ziab khaub ncaws, nws paub txog kev sib koom ua ke ntawm "decontaminated + drying + viscosity li", txhawb kev kaw-voj rov ua dua ntawm PET.

| Qhov zoo | Kev ua haujlwm tshwj xeeb |

| Molecular hnyav nce | Intrinsic viscosity (IV) tau nce ntau thiab cov neeg kho tshuab lub zog (lub zog tensile, elastic modulus) yog txhim kho los ntawm 30-50%. |

| Thermal stability optimization | Lub melting point (Tm) yog nce me ntsis (kwv yees li 5-10 ℃), crystallinity yog txhim khu kev qha, thiab lub siab kub kuj yog txhim khu kev qha (tsim rau cov cua sov-resistant lub raj mis preforms). |

| Txhim kho tshuaj purity | Tshem tawm cov monomers seem (xws li formaldehyde, acetaldehyde) thiab oligomers (cov ntsiab lus poob qis dua 50 ppm), ua tau raws li cov qauv zaub mov. |

| Yooj yim tuav cov khoom | Cov tshuaj tiv thaiv hauv lub xeev tsis txhob thermal oxidative degradation los ntawm high-temperature melting thiab yog tshwj xeeb tshaj yog haum rau zoo rov qab zoo ntawm recycled PET. |

| Txheej txheem yooj | Lub viscosity ntawm cov khoom kawg tuaj yeem tswj tau los ntawm kev kho qhov kub thiab txias, lub sijhawm thiab lub tshuab nqus tsev, yog li ua tau raws li ntau yam kev xav tau. |

Daim ntawv thov

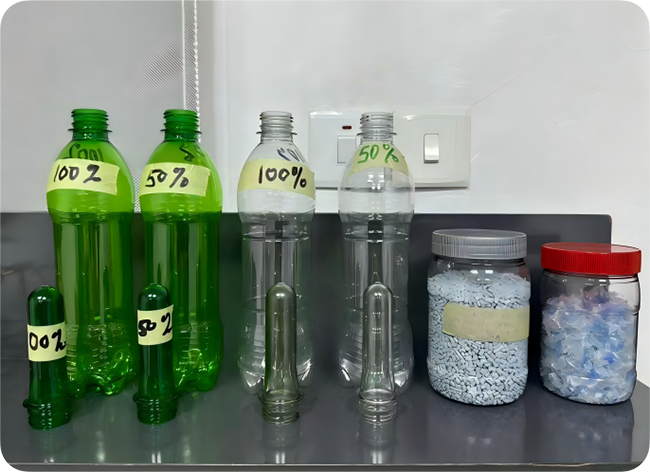

PET Preform

● High transparency fwj ntau lawm:

Txhim kho qhov sib xws ntawm PET viscosity, txo cov kev ntxhov siab tawg ntawm lub raj mis lub cev, haum rau cov dej haus carbonated, ntim cov tshuaj pleev ib ce, thiab lwm yam.

● Kev tsim kho lub raj mis kub-resistant:

Los ntawm SSP, IV tus nqi yog nce siab tshaj 0.85 dL / g, haum rau cov dej haus uas muaj cua sov (xws li ntim rau instant tshuaj yej, kas fes).

Rov ua dua tshiab PET zoo

● Recycling ntawm recycled flakes flakes:

Tom qab cov neeg siv khoom PET lub raj mis flakes raug kho nrog cov txheej txheem kev sib xyaw ua ke ntawm "kev ziab - decontaminated - viscosity li" kom tshem tawm EG, Acetaldehyde, VOC thiab rov qab viscosity, rov qab mus rau cov khoom noj khoom haus lossis qib kev lag luam (xws li fibers, nplooj ntawv).

● Circular economic nqi:

Ua ke nrog infrared drying (IRD) technology, "low-zog lub cev qhuav dej + npaum viscosity li" yog ua tiav los txhawb cov kaw-voj recycling ntawm PET

Engineering plastics teb

● Kev npaj PET ua tau zoo:

Kev tsim cov viscosity PET (IV> 1.0 dL / g) siv rau hauv cov khoom siv tsheb (xws li lub zog, cov kabmob), cov khoom siv hluav taws xob thiab hluav taws xob, thiab lwm yam, los hloov cov khoom siv hluav taws xob.