Infrared Rotary Drer + tsarin SSP

Solid-phase polymerization (SSP) shine mabuɗin fasaha don cimma "haɓaka inganci" da "sake amfani da kore" a cikin sarkar masana'antar PET.

LIANDA MACHINERY yana haɗawa sosaiINFRARED ROTARY DRYER tare da tsarin SSPdon samar da wani hadedde bayani na "Engartaccen danshi cire - Daidai danko karuwa - Low-amfani aiki". Wannan yana inganta mahimmancin abubuwan rPET na zahiri, kwanciyar hankali na thermal da tsabtar sinadarai. Wannan fasaha tana taka rawar da ba za a iya maye gurbinsa ba a cikin sarkar masana'antar PET (musamman sake yin amfani da inganci mai inganci da samar da samfur mai inganci).

Idan kuna buƙatar sanin takamaiman sigogin tsari ko tsarin kayan aiki, da fatan za a tuntuɓi Injin Lianda don samun mafita na fasaha na musamman

Matakin aiwatarwa

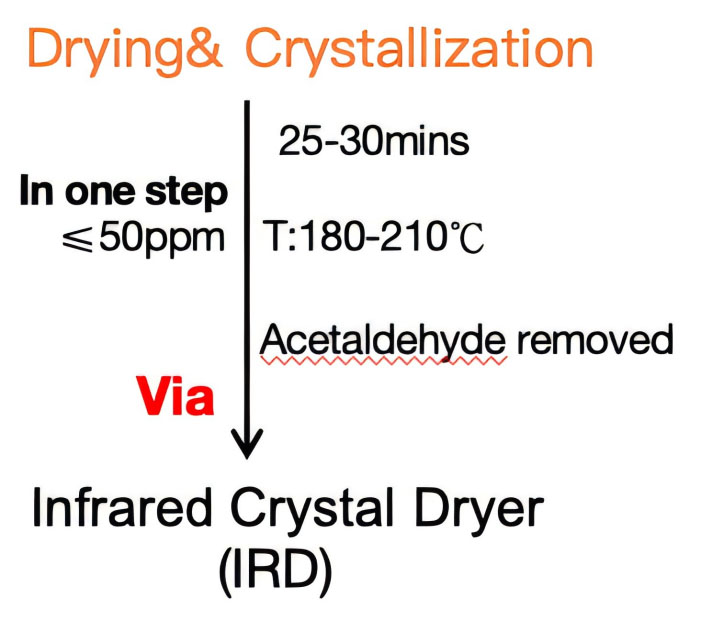

Bushewa: PET hygroscopic ne kuma yana buƙatar cire shi ta IRD (Bayan IRD, danshi na ƙarshe na PET ≤ 50 ppm) don guje wa hydrolysis da lalata a yanayin zafi mai girma.

Crystallization: PET pellets suna crystallized ta IRD (crystallization digiri ne game da 30-40%) don hana PET pellets daga mai danko ko narke a m high yanayin zafi, yayin da samar da wani barga m yanayi ga polycondensation halayen.

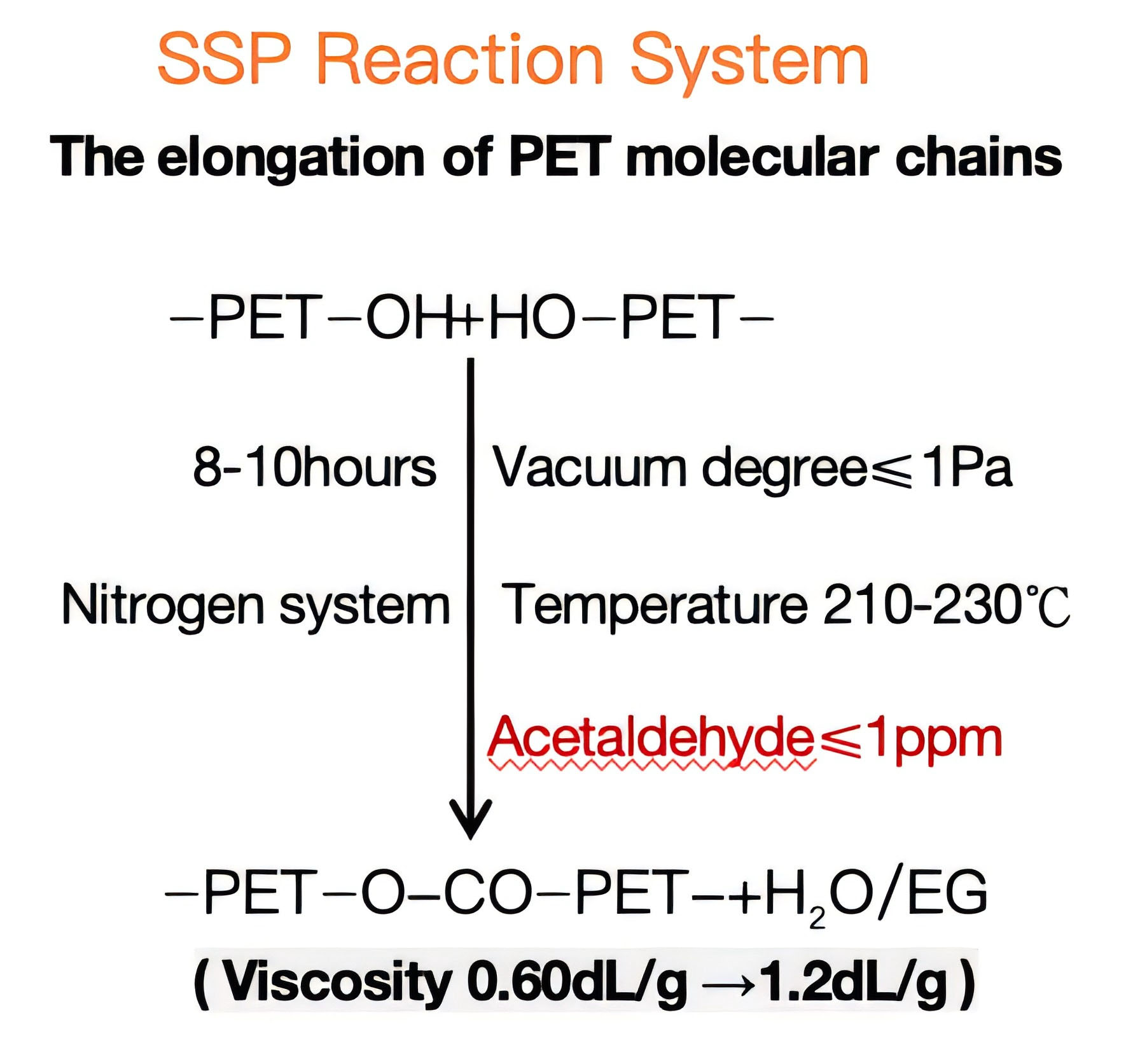

Matakin Amsa Tsakanin-lokacin Polycondensation

➢ Yanayin amsawa:

Zazzabi: sarrafawa a 200-240 ℃ (ƙasa da wurin narkewar PET 250-260 ℃, kiyaye ƙarfi).

Vacuum/inert gas kwarara: Ana gabatar da nitrogen kuma an zana injin don cire amsawar ethylene glycol (EG) da haɓaka halayen polycondensation a cikin ingantacciyar hanya.

➢ Sinadari:

Hydroxyl (-OH) da carboxyl (-COOH) a ƙarshen sarkar kwayoyin halitta ta PET suna fuskantar halayen haɓaka don samar da ester bond (-COO-), yayin da suke sakin ethylene glycol (EG), don haka sarkar kwayoyin ta ci gaba da tsawaitawa kuma nauyin kwayoyin halitta (injin danko IV) a hankali yana ƙaruwa.

Lianda Machinery integrates infrared bushewa (IRD) tare da SSP tsarin, da sauri da kuma a ko'ina heats da abu ta hanyar infrared haskoki, shortens da pretreatment lokaci, kuma optimizes da taro canja wurin yadda ya dace a cikin m lokaci dauki, sabõda haka, dukan tsarin yana da halaye na high dace da makamashi ceto, babban aiki iya aiki, da kuma high samfurin kwanciyar hankali, wanda shi ne musamman dace da high quality sake zagayowar PET.

LIANDA MAHINERY integrates Infrared crystal bushewa (IRD) tare da SSP tsarin, wanda yana amfani da infrared kalaman don sauri da kuma a ko'ina zafi kayan, gajarta da pre-jiyya lokaci, da kuma inganta taro yadda ya dace a cikin m lokaci dauki, sa dukan tsarin sosai makamashi-m, tare da babban aiki iya aiki da high samfurin kwanciyar hankali. Ya dace musamman don samar da babban inganci na PET da aka sake yin fa'ida.

Idan kuna buƙatar ƙarin cikakkun bayanai na fasaha ko mafita na musamman, zaku iya tuntuɓar Injin Lianda don tallafin ƙwararru

A hade tare da fasahar bushewa ta infrared, yana fahimtar haɗin kai na "ƙaddara + bushewa + haɓaka danko", yana haɓaka sake amfani da madauki na PET.

A hade tare da fasahar bushewa ta infrared, yana fahimtar haɗin kai na "ƙaddara + bushewa + haɓaka danko", yana haɓaka sake amfani da madauki na PET.

| Amfani | Takamaiman Ayyuka |

| Girman nauyin kwayoyin halitta | Danko na ciki (IV) yana ƙaruwa sosai kuma ƙarfin injin (ƙarfin ƙarfi, modulus na roba) yana haɓaka da 30-50%. |

| Haɓaka kwanciyar hankali na thermal | Matsayin narkewa (Tm) an ƙara ɗan ƙara kaɗan (kimanin 5-10 ℃), an inganta crystallinity, kuma ana haɓaka juriya mai zafi (wanda ya dace da preforms na kwalban zafi). |

| Ingantaccen tsarkin sinadarai | Yana kawar da saura monomers (kamar formaldehyde, acetaldehyde) da oligomers (abun ciki yana raguwa zuwa ƙasa da 50 ppm), saduwa da ƙa'idodin abinci. |

| M handling Properties | Haɓaka-ƙarfi-jihar suna guje wa lalatawar iskar oxygen ta thermal oxidative lalacewa ta hanyar narkewar zafin jiki kuma sun dace musamman don ingantaccen sabuntawa na PET da aka sake yin fa'ida. |

| Tsarin sassauci | Za'a iya sarrafa ɗankowar samfurin ƙarshe daidai ta hanyar daidaita yanayin zafi, lokaci da digiri, don haka biyan buƙatu daban-daban. |

Aikace-aikace

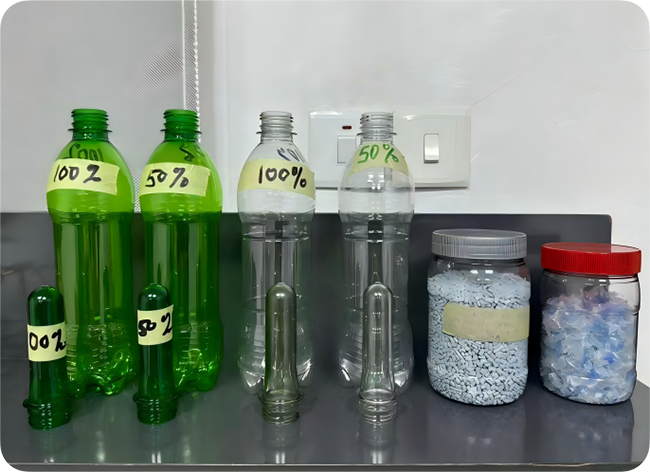

PET Preform

● Babban samar da kwalabe:

Yana haɓaka daidaituwar ɗanɗanon PET, yana rage damuwa na jikin kwalbar, wanda ya dace da abubuwan sha na carbonated, kwantena na kwaskwarima, da sauransu.

● Ci gaban kwalabe mai jure zafi:

Ta hanyar SSP, ana ƙara ƙimar IV zuwa sama da 0.85 dL/g, wanda ya dace da kwalaben abin sha mai zafi (kamar marufi don shayi nan take, kofi).

Inganta ingancin ingancin PET da aka sake yin fa'ida

● Sake yin amfani da kwalabe da aka sake yin fa'ida:

Bayan-mabukaci PET kwalban kwalban ana bi da tare da wani hadedde tsari na "bushewa - decontaminated - danko haɓakawa" don cire EG, Acetaldehyde, VOC da mayar danko, mayar da su zuwa abinci-sa ko masana'antu aikace-aikace (kamar zaruruwa, zanen gado).

● Darajar tattalin arziki madauwari:

Haɗe da fasahar bushewa ta infrared (IRD), "ƙaramar rashin kuzari + ingantaccen haɓakar danko" an samu don haɓaka sake amfani da madauki na PET

Injiniya filayen filastik

● Shirye-shiryen PET mai girma:

Samar da babban danko PET (IV> 1.0 dL / g) don amfani a cikin sassan mota (kamar gears, bearings), lantarki da gidaje na lantarki, da dai sauransu, don maye gurbin robobin injiniya na gargajiya.